I have seen some posts where authors rail against brazing done by earlier owners. I have a NOS rear clip on my bugeye that I purchased from a dealer many years ago in the early 70’s. It had the correct part number metal tag on a wire and was not an aftermarket reproduction, it’s genuine. It came with a gray paint coating, like a semi gloss (not flat) primer, and I installed it myself.

I recently had the body plastic bead blasted and it exposed some places where the factory had used brazing at the ends of the fender beads. I know most of the car was spot welded together but it appears that this was not practical for some locations so they were brazed. I guess my point here is don’t assume all brazing you find was done by a previous owner, it may be factory.

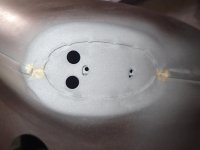

I also noticed that there were dimpled areas on the rear top of the bonnet which the factory prepped for rear view mirror installation by indenting where the screws would go. These are on both sides of the bonnet. My car has two rear view mirrors mounted through holes in the front fenders above each wheel well., so these were never used. My mirrors were not Lucas style but more like motorcycle threaded post mirrors. They are pretty useless for rear view but they look cool and are a little different so I’ll keep them. I assume maybe the selling dealer installed these mirrors, but not sure.

I recently had the body plastic bead blasted and it exposed some places where the factory had used brazing at the ends of the fender beads. I know most of the car was spot welded together but it appears that this was not practical for some locations so they were brazed. I guess my point here is don’t assume all brazing you find was done by a previous owner, it may be factory.

I also noticed that there were dimpled areas on the rear top of the bonnet which the factory prepped for rear view mirror installation by indenting where the screws would go. These are on both sides of the bonnet. My car has two rear view mirrors mounted through holes in the front fenders above each wheel well., so these were never used. My mirrors were not Lucas style but more like motorcycle threaded post mirrors. They are pretty useless for rear view but they look cool and are a little different so I’ll keep them. I assume maybe the selling dealer installed these mirrors, but not sure.

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>