Rut

Obi Wan

Offline

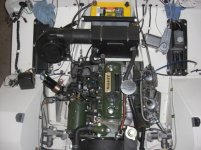

Exciting topic for sure! First time I've changed oil in a 1275 and I'm using 20w50 VR1. I noticed that on the second quart going in that the rocker assembly was under oil and the oil drained into the crankcase very slowly. Same on the third and the last I poured in as well. Is this normal? When I started her up I had pressure in the 75 to 80 psi range cold and 45 to 50 psi at idle warm. Temp averages about 180 f with the engine running for about 30 min in the garage with no aux fan blowing. Looks good to me, but the oil draining back into the crankcase so slowly got my attention.

Thanks, Rut

Thanks, Rut

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>