-

Hi Guest!

Hi Guest!

You can help ensure that British Car Forum (BCF) continues to provide a great place to engage in the British car hobby! If you find BCF a beneficial community, please consider supporting our efforts with a subscription.

There are some perks with a member upgrade!**Upgrade Now**

(PS: Subscribers don't see this gawd-aweful banner

Tips

- We have a special forum called "Member Articles" where you can submit actual articles for consideration for publication. Learn More

- Don't have an Avatar? If not, your avatar will default to the 1st character in your username. Go into "Account Details" to change your Avatar.

- Some basic forum navigation info: click

Hey - did you know if you click on the title of a thread it will take you to the first unread post since you last visited that thread?

- Hey Guest - Is your British Car Club in our Clubs database? If not, send me a PM - Basil

- Looking for a local club? Click the "Clubs" tab above and browse hundreds of clubs world-wide.

- Add Android or iPhone APP: click

- Did you know - any picture or video you add in your posts in any marque-specific forum will also get added to the Media Gallery automatically.

- A few more tips about posting and replying: click

- Hey there Guest - be sure to keep your profile page up to date with interesting info about yourself: learn more

- More tips and tricks on Posting and Replying: click

STOP!! Never post your email address in open forums. Bots can "harvest" your email! If you must share your email use a Private Message or use the

STOP!! Never post your email address in open forums. Bots can "harvest" your email! If you must share your email use a Private Message or use the  smilie in place of the real @

smilie in place of the real @

- Want to mention another member in a post & get their attention? WATCH THIS

- So, you created a "Group" here at BCF and would like to invite other members to join? Watch this!

- Hey Guest - A post a day keeps Basil from visiting you in the small hours and putting a bat up your nightdress!

- Hey Guest - do you know of an upcoming British car event?

Pretty Please - add it to our Events forum(s) and add to the calendar! >> Here's How <<

Pretty Please - add it to our Events forum(s) and add to the calendar! >> Here's How <<

- Hey Guest - you be stylin'

Change the look and feel of the forum to fit your taste. Check it out

- If you run across an inappropriate post, for example a post that breaks our rules or looks like it might be spam, you can report the post to the moderators: Learn More

- If you would like to try some different "looks" or styles for the site, scroll to the very bottom, on the left and click the Style Selector.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

TR2/3/3A A type overdrive hard engagement

- Thread starter tr3a356

- Start date

Guys, this trans project got put on hold but I'm finally back on it. I made an adapter for a pressure gauge using another plug. I have a drill on the output side spinning CCW but my drill only goes to 550 RPM. The pressure reads 200 psi when spinning and drops to 100psi and stays there when engaging the OD manually. I have two 0-600psi gauges and they correspond within 30psi. Overdrive engages and disengages. These pressures don't seem to make sense, especially with such quick engagement. I believe the OD was modified for racing. Would strong accumulator springs make it engage quickly even with low pressure? Any ideas on where to look first?

CJD

Yoda

Offline

550 RPM is ample to check the OD. Are you connecting the gage to the plug on the right side of the OD? I would expect higher pressure, and the pressure should drop at engagement, but then gradually build right back up to the accumulator shimmed spring pressure. At 200 psi you would likely have lack of engagement problems instead of hitting too hard. The plug you are looking for is about mid way up the right side of the OD.

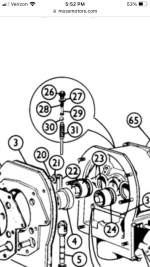

Yes, gauge is on the operating valve plug on the right side of the OD (#26). I bought another plug, drilled a hole and welded an adapter for the gauge. Pretty sure I have this right. I can't really feel it engage (but the pressure drops), however I feel the torque on the drill when it disengages and pressure goes up. It has been sitting for months so it took a while spinning it to get any pressure both starting off and when I first put it in overdrive. However, now pressure build quickly. When I stop spinning, the pressure holds but slowly starts dropping, getting to zero in 3-4 minutes.

Attachments

CJD

Yoda

Offline

Well, even though the pressure reads lower than normal, raising it will only make the shift more firm. I read through all the manuals and Buckeye articles, and cannot find anything related to hard engagement...usually lack of engagement or sticking in OD are the problems encountered.

At this point, since it is working, I would just run it. You can always use the clutch for engagements, if it hits too hard. As mentioned above, you could try a different gearbox oil, which should alter the way the shoe engages the ring.

I am curious, did it just start engaging hard or has it always done this?

At this point, since it is working, I would just run it. You can always use the clutch for engagements, if it hits too hard. As mentioned above, you could try a different gearbox oil, which should alter the way the shoe engages the ring.

I am curious, did it just start engaging hard or has it always done this?

It has always engaged OD hard since I've had it. The car did not originally come with overdrive and I bought this transmission from someone advertising it in Phoenix about 7 years ago. I remember him saying it was used in a race car. Other than some oil leaks, it shifts well, all synchros are good and no noise. I currently have it out as I did some engine work and was going to replace the seals and gaskets and wanted to investigate the hard overdrive engagement. I was just hoping there were some standard mods that a racer would use to speed up OD engagement as that would seem necessary. Past overdrives I've had seem to take about a second to engage. This one seems instantaneous and grabs fiercely. I guess I'll look into it a bit more to see if I can figure out what's going on and if not, I'll change the oil from 80/90wt gear oil to 40wt non-detergent motor oil and always use the clutch. It won't change the hard engagement but without the engine load it should put less strain on things. I'll keep you posted.

Offline

I run my rebuilt box with 40-wt non-detergent also, and always use the clutch. No need at all to stress it. There are several multipage articles here and on the web about rebuilding these that are useful even if you’re not fully rebuilding it. Jim

CJD

Yoda

Offline

Well, if I were racing, I would first raise the pressure to the max I could get by shimming the accumulator spring to the limit (or a heavier spring if I could find one)...which would take the pressure to over 400psi. This would be primarily to prevent any slipping once engaged.

Next, if I wanted faster shifts, I would ream out both the actuator valve (to release faster) and the ball seat under the valve plug (where you measure pressure), which would allow the fluid to pass to the pistons more quickly. I have never measured the diameters above, so I would not know what the sizes are stock, to see if they have been reamed out larger or not.

For a street car, I don't think the hard engagement will hurt anything. Raising the pressure would stress the pump more. So your box sounds great to me...instant shifts at a reasonable working pressure. I don't know why your pressure stays down after engaging, but I would suspect that is just the slower drill speed you are using in the test.

Next, if I wanted faster shifts, I would ream out both the actuator valve (to release faster) and the ball seat under the valve plug (where you measure pressure), which would allow the fluid to pass to the pistons more quickly. I have never measured the diameters above, so I would not know what the sizes are stock, to see if they have been reamed out larger or not.

For a street car, I don't think the hard engagement will hurt anything. Raising the pressure would stress the pump more. So your box sounds great to me...instant shifts at a reasonable working pressure. I don't know why your pressure stays down after engaging, but I would suspect that is just the slower drill speed you are using in the test.

Online

I once knew a gent that raced an MGC (with the A type OD) I saw the motor on the dyno

and it made 320HP at the crank. Point is, he never worried about the OD clutches at all.

I dont know how it could stand up to this flogging year after year, but it did.

Mad dog

and it made 320HP at the crank. Point is, he never worried about the OD clutches at all.

I dont know how it could stand up to this flogging year after year, but it did.

Mad dog

I removed the accumulator spring cover and all looked normal. The spring was not shimmed. I also looked at the non-return valve and its ball and spring looked good and the spring length was right at .75in. At this point, I don't understand the strange pressure readings or the fact that when OD is engaged, pressure drops to 100psi and stays there. The OD does not slip when driving. I tried a smaller variable drill on the output shaft that spins faster. The drill says 2000RPM but I doubt it's getting that high with the load but it's definitely faster than before. The pressure readings did not change at all so pressure seem to be maxed at 550RPM or above. At this point, I'm not going to dig any more into the overdrive as it's always worked, just harshly. It's been fine for the last 15K miles with the hard OD engagement. I'll just reseal the trans and keep using it. I'll change the oil weight and just use the clutch when engaging/disengaging to lessen the jolt.

I'll also mention that the front seal cover and other bolts are safety wired, and done quite nicely, leading me to believe that the last guy to do the trans likely was competent.

ps Anyone know of a source for the Lucas solenoid plunger boot? The original works fine and I hate to buy an inferior aftermarket solenoid just because the boot is shot.

I'll also mention that the front seal cover and other bolts are safety wired, and done quite nicely, leading me to believe that the last guy to do the trans likely was competent.

ps Anyone know of a source for the Lucas solenoid plunger boot? The original works fine and I hate to buy an inferior aftermarket solenoid just because the boot is shot.

Graham H

Jedi Warrior

Offline

I have had a good think about this issue and have come up with another solution. The low oil pressure when OD is engaged could only come from the operating piston O ring seals being in poor condition allowing them to leak under pressure and if that's the case you need to fix them because if the accumulator piston is not allowed to rise far enough to open the relief pressure ports in the cylinder there will be no oil being delivered through the drillings to the drive shaft and bearings when the OD is engaged. Changing the accumulator spring pressure only effects the maximum oil pressure before the piston reaches the relief ports in the cylinder.

I think from memory there are 8 clutch pressure springs, half slightly shorter than the the rest with an identifying colour on each one and I read where someone fitted them in the wrong places and the OD would not engage. If you want it to operate properly you will need to take it apart and inspect those areas mentioned and now that you have adapted the pressure gauge you could add an air pressure fitting to help reassembly . Without air pressure to engage the OD you will battle for ever to re-aline the final splines in the OD and possible bend or brake the adapter plate.

Good luck Graham

I think from memory there are 8 clutch pressure springs, half slightly shorter than the the rest with an identifying colour on each one and I read where someone fitted them in the wrong places and the OD would not engage. If you want it to operate properly you will need to take it apart and inspect those areas mentioned and now that you have adapted the pressure gauge you could add an air pressure fitting to help reassembly . Without air pressure to engage the OD you will battle for ever to re-aline the final splines in the OD and possible bend or brake the adapter plate.

Good luck Graham

Offline

I've also been thinking about this a bit and had the following thoughts.

1. I have a hard time imagining that 100 PSI would be enough to move the sliding member and keep the OD engaged, when it is designed for ~360 PSI. If it is engaging at this pressure, it is just barely doing so.

2. When you engage the OD, the pressure should drop momentarily and then quickly rise to the original 360 PSI value, not remain low.

So, clearly, something is wrong with the pressure or the measurement. Since the OD appears to be engaging and disengaging as it should, I suspect the measurement. I think this has to be resolved before we can say much more.

One important point: the condition of the balls in the antireturn valve and actuator valve are critical. Even small scratches can cause a drop in pressure, although it's hard for me to imagine a 200 PSI decrease unless the scratch is pretty obvious.

You also might want to check the way that the pressure gauge is connected to the OD. It would not be hard to do that in a way that interfered with the ball in the actuating valve, and lose fluid through the return orifice.

As for the original question, re hard engagement: you are suddenly switching in a gear with a 0.8 ratio. I have a hard time seeing how that would not cause hard engagement. In mine, the shock is tolerable in 4th gear, but not in lower gears, so I always clutch it. Also, I would think that low pressure, if anything, would cause softer, not harder, engagement.

1. I have a hard time imagining that 100 PSI would be enough to move the sliding member and keep the OD engaged, when it is designed for ~360 PSI. If it is engaging at this pressure, it is just barely doing so.

2. When you engage the OD, the pressure should drop momentarily and then quickly rise to the original 360 PSI value, not remain low.

So, clearly, something is wrong with the pressure or the measurement. Since the OD appears to be engaging and disengaging as it should, I suspect the measurement. I think this has to be resolved before we can say much more.

One important point: the condition of the balls in the antireturn valve and actuator valve are critical. Even small scratches can cause a drop in pressure, although it's hard for me to imagine a 200 PSI decrease unless the scratch is pretty obvious.

You also might want to check the way that the pressure gauge is connected to the OD. It would not be hard to do that in a way that interfered with the ball in the actuating valve, and lose fluid through the return orifice.

As for the original question, re hard engagement: you are suddenly switching in a gear with a 0.8 ratio. I have a hard time seeing how that would not cause hard engagement. In mine, the shock is tolerable in 4th gear, but not in lower gears, so I always clutch it. Also, I would think that low pressure, if anything, would cause softer, not harder, engagement.

Graham H

Jedi Warrior

Offline

Another area to check for low oil pressure is the non-return valve ball bearing for the oil pump, which may have been left in when the pump was removed. If this were the case it would have scoured the casting which allows it to bypass under pressure. This can be repaired with JB weld or similar but if you go down that path, make sure you take the non-return valve ball and spring out before you press the bump cylinder out.

Graham

Graham

Just wanted to give an update and close this thread. I decided to change to Valvoline VR-1 20W50 and reinstalled the trans after the engine work was completed. It still engages OD harshly but not quite as bad as before with the lighter oil. I'll just use the clutch. Otherwise, everything works great.

RichB4493

Member

Offline

I recall a guide that talks about the amount of ball lift in the operation valve and the duration of time it takes for engagement. I’ll see if I can find it. When measured with a plunge micrometer I believe the lift should be .01-.016”. It’s in Part IV of the Buckeye Triumph OD documents.Just wanted to give an update and close this thread. I decided to change to Valvoline VR-1 20W50 and reinstalled the trans after the engine work was completed. It still engages OD harshly but not quite as bad as before with the lighter oil. I'll just use the clutch. Otherwise, everything works great.

Lots of good troubleshooting and setting up advice in there.