AUSMHLY

Yoda

Offline

Hello all,

Does anyone have any photos of the original Transmission Heat Deflector and Seal installed on the BN1-BN7 cars?

British Cars Specialist sells one, but not sure if it's the original material or not.

The material is not as important for me as is a photo showing the original in the car.

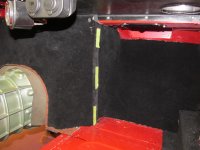

I'm making a seal for my BJ8 and would like to show the original for the BN1-BN7 series and the comparison of what I'm making and how to install it in the BJ7-BJ8.

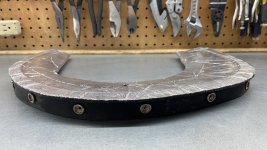

I'll include a photo (from BCS drawing) of the two pieces, metal deflector and the seal for reference.

Thank you in advance.

Does anyone have any photos of the original Transmission Heat Deflector and Seal installed on the BN1-BN7 cars?

British Cars Specialist sells one, but not sure if it's the original material or not.

The material is not as important for me as is a photo showing the original in the car.

I'm making a seal for my BJ8 and would like to show the original for the BN1-BN7 series and the comparison of what I'm making and how to install it in the BJ7-BJ8.

I'll include a photo (from BCS drawing) of the two pieces, metal deflector and the seal for reference.

Thank you in advance.

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>