I drank a beer and realized I had moved the pulley, so I found the compression stroke and went to the TDC mark and the distributor dropped right in. Duh. I think I am done with TDC and the distributor. The major new finding was the points being too closed. I started and drove a short distance and it would not idle at all and did not run smooth but it does run. I would not take it anywhere like this. So I checked my butterflies again using the pedal and dang it they are not fully opening. They are close but not horizontal. I will check tomorrow but I think they open if I pull the lever in the engine compartment. I know about the bolt under the pedal. I am not sure what else to adjust to get them to open but I will work on it. The butterflies need to open but that cannot be causing my problem (not smooth, lack of power). So, I will pull a plug look at it, disconnect the fuel line and see what comes out and get back on the carbs. Steve - I will have to turn the idle up at the carbs to keep it running but I will then use the knurled knob and do what you say. Isn't timing and dwell the same thing? This is frustrating the heck out of me but I am learning alot. Bruce

-

Hi Guest!

Hi Guest!

If you appreciate British Car Forum and our 25 years of supporting British car enthusiasts with technical and anicdotal information, collected from our thousands of great members, please support us with a low-cost subscription. You can become a supporting member for less than the dues of most car clubs.

There are some perks with a member upgrade!**Upgrade Now**

(PS: Subscribers don't see this gawd-aweful banner

Tips

- We have a special forum called "Member Articles" where you can submit actual articles for consideration for publication. Learn More

- Don't have an Avatar? If not, your avatar will default to the 1st character in your username. Go into "Account Details" to change your Avatar.

- Some basic forum navigation info: click

Hey - did you know if you click on the title of a thread it will take you to the first unread post since you last visited that thread?

- Hey Guest - Is your British Car Club in our Clubs database? If not, send me a PM - Basil

- Looking for a local club? Click the "Clubs" tab above and browse hundreds of clubs world-wide.

- Add Android or iPhone APP: click

- Did you know - any picture or video you add in your posts in any marque-specific forum will also get added to the Media Gallery automatically.

- A few more tips about posting and replying: click

- Hey there Guest - be sure to keep your profile page up to date with interesting info about yourself: learn more

- More tips and tricks on Posting and Replying: click

STOP!! Never post your email address in open forums. Bots can "harvest" your email! If you must share your email use a Private Message or use the

STOP!! Never post your email address in open forums. Bots can "harvest" your email! If you must share your email use a Private Message or use the  smilie in place of the real @

smilie in place of the real @

- Want to mention another member in a post & get their attention? WATCH THIS

- So, you created a "Group" here at BCF and would like to invite other members to join? Watch this!

- Hey Guest - A post a day keeps Basil from visiting you in the small hours and putting a bat up your nightdress!

- Hey Guest - do you know of an upcoming British car event?

Pretty Please - add it to our Events forum(s) and add to the calendar! >> Here's How <<

Pretty Please - add it to our Events forum(s) and add to the calendar! >> Here's How <<

- Hey Guest - you be stylin'

Change the look and feel of the forum to fit your taste. Check it out

- If you run across an inappropriate post, for example a post that breaks our rules or looks like it might be spam, you can report the post to the moderators: Learn More

- If you would like to try some different "looks" or styles for the site, scroll to the very bottom, on the left and click the Style Selector.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

TR4/4A Some Help with Setting Distributor

- Thread starter bammons

- Start date

Offline

Dwell and timing are not the same thing. They relate to each other in point gap, a bit. IGNORE dwell. I agree that your problem at top end is not timing. It is fuel or throttle.

Bob

Bob

If you are running SUs , the connection rod that holds the 2 carbs together so they can work in unison can come lose, and you will have the problem you describe because you are running on 1 carb. I think you must have looked at the rotor position wrong with that weird stock dizy cap because the engine ran fine at start up before, or turned the engine 180. please keep us posted i cannot sleep

Set the points at .015 and you should be fine; dwell is just another way of reading the gap on the points. We all went through what you are doing at some point with our cars. This is a good education. Do you have timing light and dwell meter? A timing light will let you see the distributor advancement which could be you problem also. The dwell meter will let you see the point gap with the engine running. They both hook up easily, but if you have positive ground hook them up power to positive ground on the body.

steve

steve

I have gone back to the carbs. After my short drive yesterday I pulled a plug and it looks lean but I may not have driven it long enough. I took Charley's advice and disconnected the fuel line and operated the fuel pump lever 25 times after I got the first drizzle (see picture). This is a Moss replacement pump. This does not seem anywhere near enough is it? In addition, I have had my wife step on the pedal and the butterflies are near open (see bad pic) but not 100%. For some reason I can pull the pedal lever and/or push down on the vertical linkage and get 100% open. If I shorten the vertical link then the stop does not hit the underside of the connecting rod and in order to shorten the long linkage (pic) I think I will have to cut some off one or both ends. The car runs like crap. I no longer have any hair as I have pulled it all out. Help! Bruce

Attachments

charleyf

Luke Skywalker

Offline

The butterfly looks close enough to be able to give you full throttle IMHO.I have gone back to the carbs. After my short drive yesterday I pulled a plug and it looks lean but I may not have driven it long enough. I took Charley's advice and disconnected the fuel line and operated the fuel pump lever 25 times after I got the first drizzle (see picture). This is a Moss replacement pump. This does not seem anywhere near enough is it? In addition, I have had my wife step on the pedal and the butterflies are near open (see bad pic) but not 100%. For some reason I can pull the pedal lever and/or push down on the vertical linkage and get 100% open. If I shorten the vertical link then the stop does not hit the underside of the connecting rod and in order to shorten the long linkage (pic) I think I will have to cut some off one or both ends. The car runs like crap. I no longer have any hair as I have pulled it all out. Help! Bruce

I would not chase the linkage any more.

As to the fuel pump. I am guessing that you had the line drained prior to the 25 pumps. So what are you getting with about 5 pumps after you have established the flow? How close would you come to filling a whiskey shot glass?

Charley

I have never check a fuel pump delivery problem with the lever before; it might work great, I hope it does I will do it next time.

What I do is get a clean jar, unhook the fuel line at the pump or carb whatever is easiest, put the fuel line end in the jar and turn the car with the key about 5 pumps. You will know right away if the pumps work because the volume is high. You will say that has to be enough or not

What I do is get a clean jar, unhook the fuel line at the pump or carb whatever is easiest, put the fuel line end in the jar and turn the car with the key about 5 pumps. You will know right away if the pumps work because the volume is high. You will say that has to be enough or not

charleyf

Luke Skywalker

Offline

That probably works better. As the actual location of the pump arm on the cam may not allow a full stroke with each hand pump.I have never check a fuel pump delivery problem with the lever before; it might work great, I hope it does I will do it next time.

What I do is get a clean jar, unhook the fuel line at the pump or carb whatever is easiest, put the fuel line end in the jar and turn the car with the key about 5 pumps. You will know right away if the pumps work because the volume is high. You will say that has to be enough or not

Charley

Offline

Adding to my post 22, I agree with Nutmeg that ignition parts other than the dist. could be at fault, primarily the coil and condenser. Additionaly the spring that closes the points can fatigue (lose springiness), allowing the points to float and not close at high RPM.

Bob

Bob

If a bartender served me a shot glass that only had that much I would ask for a refund. The glass jar was 2 1/2" base and fuel was 1/4" above the glass. But I like SP's method and will do that. I primed the line until I saw the first "drizzle" and gave 25 pumps after that to get that short shot glass. Five pumps would have been very little. Have to go see the new GDau tomorrow so won't be able to test until Sunday. Glad to hear the butterflies look OK I have had to work on the linkage (some corrections) to get to that. I will mention I have the original fuel pump and a rebuild kit but don't want to change it unless needed. Nutmeg I would be glad to test the coil if you will tell me how. It is a Lucas Sport Coil 3ohm that pre-dates me to about 1980.

Bruce

Bruce

Offline

Ditto on Nutmeg's post 32. Maybe we could make better guesses if you could tell us when and how this came up. A little worse every day for a period of time? Ran well on Thursday and the fault came up full formed on Friday when you got in it? Was fine when you parked it and you went back to it some while later and found it in failure? Any home test you can make on the coil is not going to be duplicating running conditions where the problem shows. Sounds like you may have found a fuel supply problem, though. Do you have an in-line filter? When did you l;ast change it? Blow some compressed air back thru the fuel line to cclear any possible clog at the pick up.

Bob

Bob

Offline

Bammon . The best fuel pump is an (OE) that has been gone through with the good kit.

On any good pump, a single trust on the lever should shoot a gush of fuel 10 or 12 inches.

For many years the pumps out of India have set a very low bar indeed (to say it kindly)

Sadly the symptoms you have classic.

When you get the kit be aware that the notch in the diaphragm rod is often too rough to

fit into the slot in the arm. Assemble it without the spring as a test, it should go in and turn 90

degrees and lock in. File the notch a bit to make it fit if you need to.

Once this fits well ,change out the lower seal inside the body ,install the spring and place the

diaphragm in and lock it in place. The rest is easy. But make no mistake, you can never fix the AM

pump ,it is fatally flawed. File 13 the bugger.

Mad dog

On any good pump, a single trust on the lever should shoot a gush of fuel 10 or 12 inches.

For many years the pumps out of India have set a very low bar indeed (to say it kindly)

Sadly the symptoms you have classic.

When you get the kit be aware that the notch in the diaphragm rod is often too rough to

fit into the slot in the arm. Assemble it without the spring as a test, it should go in and turn 90

degrees and lock in. File the notch a bit to make it fit if you need to.

Once this fits well ,change out the lower seal inside the body ,install the spring and place the

diaphragm in and lock it in place. The rest is easy. But make no mistake, you can never fix the AM

pump ,it is fatally flawed. File 13 the bugger.

Mad dog

I'm not trying to be a smart ass but why not just install a 2.5 psi electric fuel pump? You get instant starts and like Randall used to say your starter will thank you for it.Bammon . The best fuel pump is an (OE) that has been gone through with the good kit.

On any good pump, a single trust on the lever should shoot a gush of fuel 10 or 12 inches.

For many years the pumps out of India have set a very low bar indeed (to say it kindly)

Sadly the symptoms you have classic.

When you get the kit be aware that the notch in the diaphragm rod is often too rough to

fit into the slot in the arm. Assemble it without the spring as a test, it should go in and turn 90

degrees and lock in. File the notch a bit to make it fit if you need to.

Once this fits well ,change out the lower seal inside the body ,install the spring and place the

diaphragm in and lock it in place. The rest is easy. But make no mistake, you can never fix the AM

pump ,it is fatally flawed. File 13 the bugger.

Mad dog

Offline

Karl , the race car had 3 fuel pumps.It was always necessary to have a spare in the kit.

In short, never has a good mechanical pump let me down, but I have lost track of the electric

ones I have had to replace over the years.To say nothing of the crummy fuel pressure

regulators that waste gas.( K.IS.S.) The kit to restore the OE pump is very cheap also, appeals to

the Scotsman in me(Canaday) Call me crazy (my wife does).

Mad dog

In short, never has a good mechanical pump let me down, but I have lost track of the electric

ones I have had to replace over the years.To say nothing of the crummy fuel pressure

regulators that waste gas.( K.IS.S.) The kit to restore the OE pump is very cheap also, appeals to

the Scotsman in me(Canaday) Call me crazy (my wife does).

Mad dog

Some of this was in my first post. Car restored and put on road last May. Rode easy on it thru break -in, after break-in started noticing lack of power in upper gears. Would cruise OK (say 60-65) but not much power. After put in for the season I started looking at things and yes it has gone down hill from there. I have fixed slop in the pedal assembly, corrected incorrectly installed linkage, had to reset float bowls, had to reset valve clearance, had to reset points, altered to original fit a Moss bell crank, worked to get the butterflies to open fully or nearly so. Now the car is fighting me to go up the RPMs and is not smooth. Did not suspect some of these things because I had a mechanic finalize the engine in terms of getting it running and in the case of the fuel pump as it was new. But I do suspect a fuel problem so after looking at any issues at the distributor /timing and am back once again looking at fuel. All fuel lines are new (as of last year) the fuel filter is new there is a very small amount of trash in the bottom, the fuel tank has been coated (Red Cote by me). Engine was rebuilt by me. I don't want to run a electric fuel pump unless I have to. Today I will use the key instead of the fuel priming lever and see what happens. Is there a trick to getting the fuel pump lever that engages the cam to seat properly? Is there any way I installed the new pump last year wrong? Mad Dog as stated above the priming lever does not squirt hardly any fuel and after 25 pumps I got practically nothing (see above) so basically, I have a diagnosis on the fuel pump as bad. I will install the rebuild kit and get the old one installed. Bruce

Offline

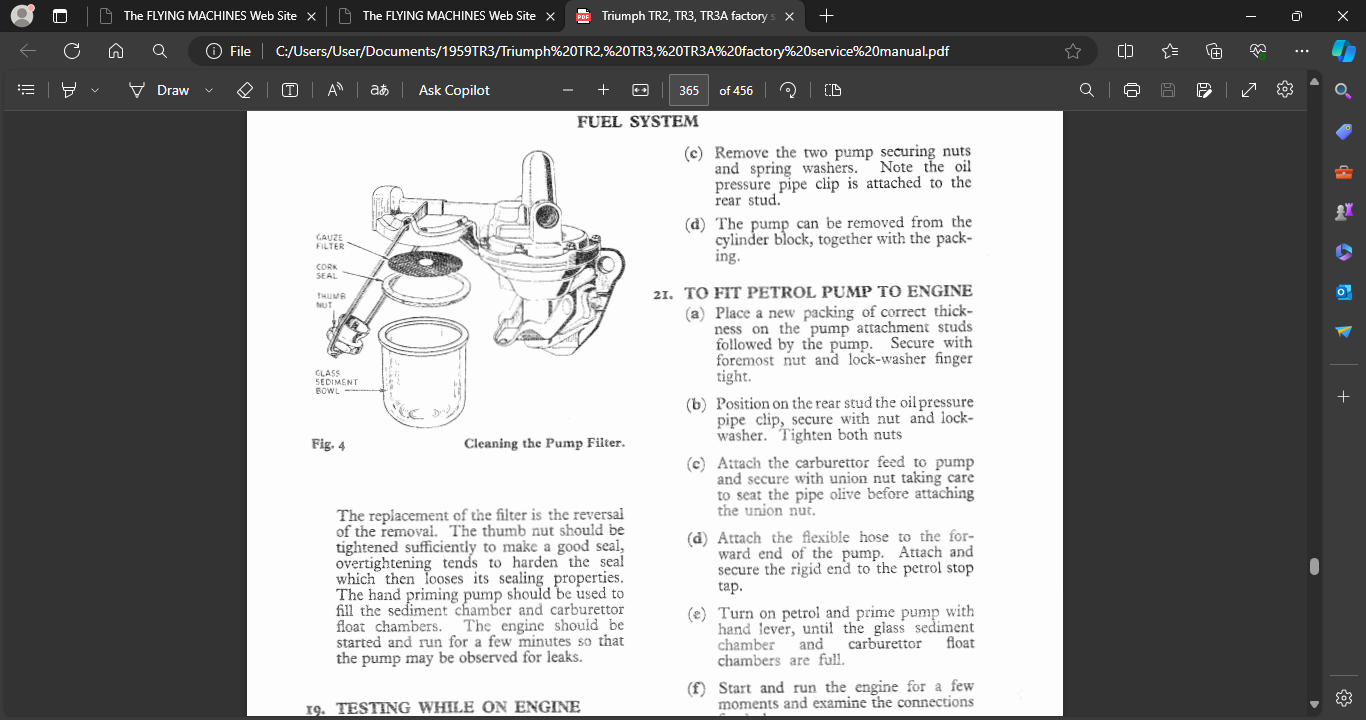

Just my two cents again, but I remember my TR3 had a spacer (packing) between engine and fuel pump, to give the arm proper setting against the operating cam inside the engine. See section 21 below.

Is it possible the TR4 also had a pump spacer? Incorrect spacer thickness could cause incorrect operation of the pump. Also note, the camshaft must be in the correct position before inserting the pump arm.

Just a thought.

Tom M.

Is it possible the TR4 also had a pump spacer? Incorrect spacer thickness could cause incorrect operation of the pump. Also note, the camshaft must be in the correct position before inserting the pump arm.

Just a thought.

Tom M.

Last edited:

Ok did the fuel test using the key (starter) instead of the primer lever. I have a gear reduction starter so it spins faster than stock. This is about 6-7 seconds of pumping and yielded say 3 oz of gas. Much more than the primer lever method but is it what it should be? I will wait for answers before doing anything. Bruce

![IMG_3541[1].JPG](/community/data/attachments/72/72499-4b635b5a7a449e826ff65120aaf40d1d.jpg)

![IMG_3547[1].JPG](/community/data/attachments/72/72500-4c4c8f43e82d64460dd572ccf5158cb0.jpg)

![IMG_3548[1].JPG](/community/data/attachments/72/72501-a059982cccbb4991caac0c1ec75f8878.jpg)

![IMG_3551[1].JPG](/community/data/attachments/72/72534-ad1c2b5763197ddaa03b9ab28d8793d9.jpg)