RonC

Freshman Member

Offline

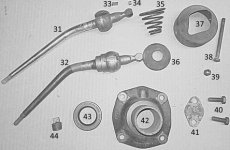

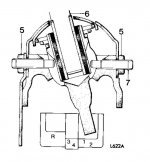

I have 2 seasons on my J Type OD tranny transplanted into my TR3A. Shifting difficulty I have had is finding 3rd moving from 2nd and also cleanly down to 4th. I want to remedy and in revisiting my conversion I have a few thoughts on cause. Without enough downward pressure by spring, the shifter end migrates up the shoulder of rail?

The profile for the TR6 shifter shows a collar raising the large spring thus tensioning under cap? The flat ball type of the TR3 could be not giving enough downward spring pressure? Also I read about a rubber hose and washer placed under the top cap as a fix to add a limiter under shifter cap? How did this work?

If I do need to change to a TR6 style shift ball arrangement, I was toying with the idea of removing the longer curved shifter handle since I think it's splined. I could cut off a straight TR3 handle and possibly weld to the TR6 ball unit?

The profile for the TR6 shifter shows a collar raising the large spring thus tensioning under cap? The flat ball type of the TR3 could be not giving enough downward spring pressure? Also I read about a rubber hose and washer placed under the top cap as a fix to add a limiter under shifter cap? How did this work?

If I do need to change to a TR6 style shift ball arrangement, I was toying with the idea of removing the longer curved shifter handle since I think it's splined. I could cut off a straight TR3 handle and possibly weld to the TR6 ball unit?

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>