Anyone know the size of the "L bracket" screws for the upper frame? Mine are rusted out....or do I have to buy the whole kit? Also...I don't see the bolts that bolt the stanchion to the cowl in the Moss cataloque? I don't have the Ddzus type with the plate. Anyone know the size of these bolts or who sells them.

-

Hi Guest!

Hi Guest!

You can help ensure that British Car Forum (BCF) continues to provide a great place to engage in the British car hobby! If you find BCF a beneficial community, please consider supporting our efforts with a subscription.

There are some perks with a member upgrade!**Upgrade Now**

(PS: Subscribers don't see this gawd-aweful banner

Tips

- We have a special forum called "Member Articles" where you can submit actual articles for consideration for publication. Learn More

- Don't have an Avatar? If not, your avatar will default to the 1st character in your username. Go into "Account Details" to change your Avatar.

- Some basic forum navigation info: click

Hey - did you know if you click on the title of a thread it will take you to the first unread post since you last visited that thread?

- Hey Guest - Is your British Car Club in our Clubs database? If not, send me a PM - Basil

- Looking for a local club? Click the "Clubs" tab above and browse hundreds of clubs world-wide.

- Add Android or iPhone APP: click

- Did you know - any picture or video you add in your posts in any marque-specific forum will also get added to the Media Gallery automatically.

- A few more tips about posting and replying: click

- Hey there Guest - be sure to keep your profile page up to date with interesting info about yourself: learn more

- More tips and tricks on Posting and Replying: click

STOP!! Never post your email address in open forums. Bots can "harvest" your email! If you must share your email use a Private Message or use the

STOP!! Never post your email address in open forums. Bots can "harvest" your email! If you must share your email use a Private Message or use the  smilie in place of the real @

smilie in place of the real @

- Want to mention another member in a post & get their attention? WATCH THIS

- So, you created a "Group" here at BCF and would like to invite other members to join? Watch this!

- Hey Guest - A post a day keeps Basil from visiting you in the small hours and putting a bat up your nightdress!

- Hey Guest - do you know of an upcoming British car event?

Pretty Please - add it to our Events forum(s) and add to the calendar! >> Here's How <<

Pretty Please - add it to our Events forum(s) and add to the calendar! >> Here's How <<

- Hey Guest - you be stylin'

Change the look and feel of the forum to fit your taste. Check it out

- If you run across an inappropriate post, for example a post that breaks our rules or looks like it might be spam, you can report the post to the moderators: Learn More

- If you would like to try some different "looks" or styles for the site, scroll to the very bottom, on the left and click the Style Selector.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

TR2/3/3A Another windshield question...bolts and screws?

- Thread starter karls59tr

- Start date

TR3driver

Great Pumpkin - R.I.P

Offline

Sorry, I can't really help there. Mine didn't give me enough trouble to remember them. Most of the frames were chromed brass, though, so that's probably what you have. I've only ever seen one of the aluminum ones. One way to tell is to look at the Tenax pegs for the soft top; on the aluminum frames there is a slotted screw head visible on the side opposite the peg.

One tool I've found useful in similar situations is a "hand impact tool" https://www.northerntool.com/shop/tools/product_36882_36882

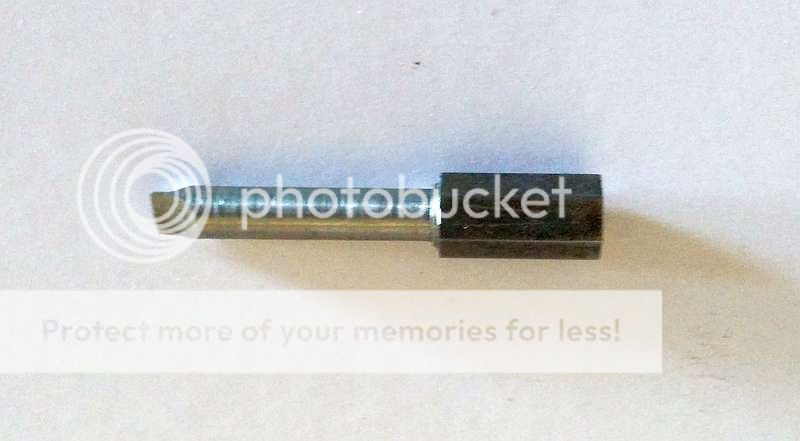

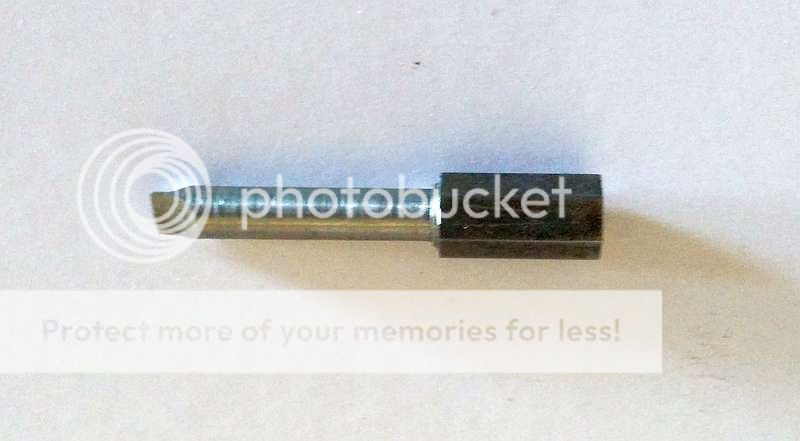

Mine takes 5/16" hex bits, so it's fairly easy to fashion a custom bit from a 5/16" Allen wrench. Here's the one I made for some tiny plugs on an old tractor carb last year:

Try to get the tip to be a snug fit in the slot, as that lessens the chance of stripping it.

I forgot to take photos of the little ones, but here's a shot where you can see one of the bigger ones. Some of the little ones were down holes (which is why the tool is so long). I couldn't budge any of them with an ordinary screwdriver, but all but one came out with no damage using the impact tool and custom bit.

One tool I've found useful in similar situations is a "hand impact tool" https://www.northerntool.com/shop/tools/product_36882_36882

Mine takes 5/16" hex bits, so it's fairly easy to fashion a custom bit from a 5/16" Allen wrench. Here's the one I made for some tiny plugs on an old tractor carb last year:

Try to get the tip to be a snug fit in the slot, as that lessens the chance of stripping it.

I forgot to take photos of the little ones, but here's a shot where you can see one of the bigger ones. Some of the little ones were down holes (which is why the tool is so long). I couldn't budge any of them with an ordinary screwdriver, but all but one came out with no damage using the impact tool and custom bit.

martx-5

Yoda

Offline

Anyone know the size of the "L bracket" screws for the upper frame? Mine are rusted out....or do I have to buy the whole kit? Also...I don't see the bolts that bolt the stanchion to the cowl in the Moss cataloque? I don't have the Ddzus type with the plate. Anyone know the size of these bolts or who sells them.

I believe that the small "L" bracket screws are 4BA. Get the kit.

Moss shows the stanchion bolts as 320-490...under part 54 in link...

https://www.mossmotors.com/Shop/ViewProducts.aspx?PlateIndexID=29161

However, I bought those from Moss about 8 years ago and the didn't fit my stanchions. The head diameter was too large. I had to cut them down on a lathe. It wasn't much, but enough to aggravate. I don't know if their current stock fits properly.

martx-5

Yoda

Offline

... If too large could the heads on the screws be Filed down?

If you're talking about the oversize stanchion screws from Moss that I mentioned above, then yes, they probably could be filed, although a grinder would work just as well. Realize though, that you will also be removing the chrome plating along the edge by cutting down the head diameter.

Donald1107

Senior Member

Offline

Question (I think I’m screwed ): how do you retrieve the “captured” bolt inside the cowling on a TR3A that receives the bolt that holds the windshield stanchion on the guide plate? One of the two that hold my left stanchion to the guide plate apparently came loose and dropped “who knows where.” See attached photo.”

): how do you retrieve the “captured” bolt inside the cowling on a TR3A that receives the bolt that holds the windshield stanchion on the guide plate? One of the two that hold my left stanchion to the guide plate apparently came loose and dropped “who knows where.” See attached photo.”

Attachments

charleyf

Luke Skywalker

Offline

From inside the car at the top of the foot well is a metal panel that covers/hides those welded on nuts.Question (I think I’m screwed): how do you retrieve the “captured” bolt inside the cowling on a TR3A that receives the bolt that holds the windshield stanchion on the guide plate? One of the two that hold my left stanchion to the guide plate apparently came loose and dropped “who knows where.” See attached photo.”

If I were in this situation, I would locate where on that inner panel is directly behind where the missing nut was. Maybe a long drill to do that. Then I would create a hole large enough to be able to insert a replacement nut and a socket to hold it. Remember to take into account any angle so you are working at 90 degrees from the outer panel.

Use a new nut . Unless you want to dismantle your car there is no sense looking for the old nut.

Charley

Interesting I have never saw a set up exactly like that where there is a bolt and not a screw. The bolt looks chromed and stock. In addition, I never saw the guide plates using thread bolts and not using dzus fitting which screw to the body to slide the windshield in place.

I had a 1961 where the windshield simple screwed into the body with screws like you see in a Moss catalogue without a guide plate.

I traded some guide plates to a guy in Canada because I could not figure out a way to use them. Is the car a 1960?

Charley’s plan seems to me the only you can fix it and should work fine.

steve

I had a 1961 where the windshield simple screwed into the body with screws like you see in a Moss catalogue without a guide plate.

I traded some guide plates to a guy in Canada because I could not figure out a way to use them. Is the car a 1960?

Charley’s plan seems to me the only you can fix it and should work fine.

steve

Donald1107

Senior Member

Offline

It is a 1959. And thank you, Charlie, for a good idea. I was considering a KeenSert thread repair insert. But I like this option to go through the inside panel.

you guys are great!

you guys are great!

Donald1107

Senior Member

Offline

TS46231L is the VIN. I bought it in 1986, in terrible mechanical condition, but original blue upholstery with white piping and decent paint. I don’t know what a former owner did to it other than put the pistons back in without rings. (The engine actually ran … poorly-duh).

Donald1107

Senior Member

Offline

This worked great. The space between ‘em the outside guide plate and the panel inside the driver’s foot well was only 1 1/2”, and I could put a 3/8” drill all the way through. So a 2” course thread bolt with a large washer and nut holds the stanchion firmly to the guide plate. Thanks!!!