For various reasons, I'm removing the carbon cannister and associated piping from my 1973 TR6. I've already gone with a vacuum advance distributor in place of the original vacuum retard. A few questions; (1) Do the fuel bowl vents on the Strombergs need to be maintained or can they simply be capped? (2) Is it a good idea to simply run the crankcase vent (from the rocker cover) straight to the original carburetor ports and capping the line that went to the carbon cannister, or could performance be enhanced by capping the carburetor ports and running the crankcase vent to something like a puke tank? I know the carburetors provided a slight vacuum to assist crankcase ventilation (hence the term PCV?) but is that really necessary?

-

Hi Guest!

Hi Guest!

You can help ensure that British Car Forum (BCF) continues to provide a great place to engage in the British car hobby! If you find BCF a beneficial community, please consider supporting our efforts with a subscription.

There are some perks with a member upgrade!**Upgrade Now**

(PS: Subscribers don't see this gawd-aweful banner

Tips

- We have a special forum called "Member Articles" where you can submit actual articles for consideration for publication. Learn More

- Don't have an Avatar? If not, your avatar will default to the 1st character in your username. Go into "Account Details" to change your Avatar.

- Some basic forum navigation info: click

Hey - did you know if you click on the title of a thread it will take you to the first unread post since you last visited that thread?

- Hey Guest - Is your British Car Club in our Clubs database? If not, send me a PM - Basil

- Looking for a local club? Click the "Clubs" tab above and browse hundreds of clubs world-wide.

- Add Android or iPhone APP: click

- Did you know - any picture or video you add in your posts in any marque-specific forum will also get added to the Media Gallery automatically.

- A few more tips about posting and replying: click

- Hey there Guest - be sure to keep your profile page up to date with interesting info about yourself: learn more

- More tips and tricks on Posting and Replying: click

STOP!! Never post your email address in open forums. Bots can "harvest" your email! If you must share your email use a Private Message or use the

STOP!! Never post your email address in open forums. Bots can "harvest" your email! If you must share your email use a Private Message or use the  smilie in place of the real @

smilie in place of the real @

- Want to mention another member in a post & get their attention? WATCH THIS

- So, you created a "Group" here at BCF and would like to invite other members to join? Watch this!

- Hey Guest - A post a day keeps Basil from visiting you in the small hours and putting a bat up your nightdress!

- Hey Guest - do you know of an upcoming British car event?

Pretty Please - add it to our Events forum(s) and add to the calendar! >> Here's How <<

Pretty Please - add it to our Events forum(s) and add to the calendar! >> Here's How <<

- Hey Guest - you be stylin'

Change the look and feel of the forum to fit your taste. Check it out

- If you run across an inappropriate post, for example a post that breaks our rules or looks like it might be spam, you can report the post to the moderators: Learn More

- If you would like to try some different "looks" or styles for the site, scroll to the very bottom, on the left and click the Style Selector.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

TR6 Removing the charcoal cannister considerations

- Thread starter Ribbs

- Start date

poolboy

Yoda

Offline

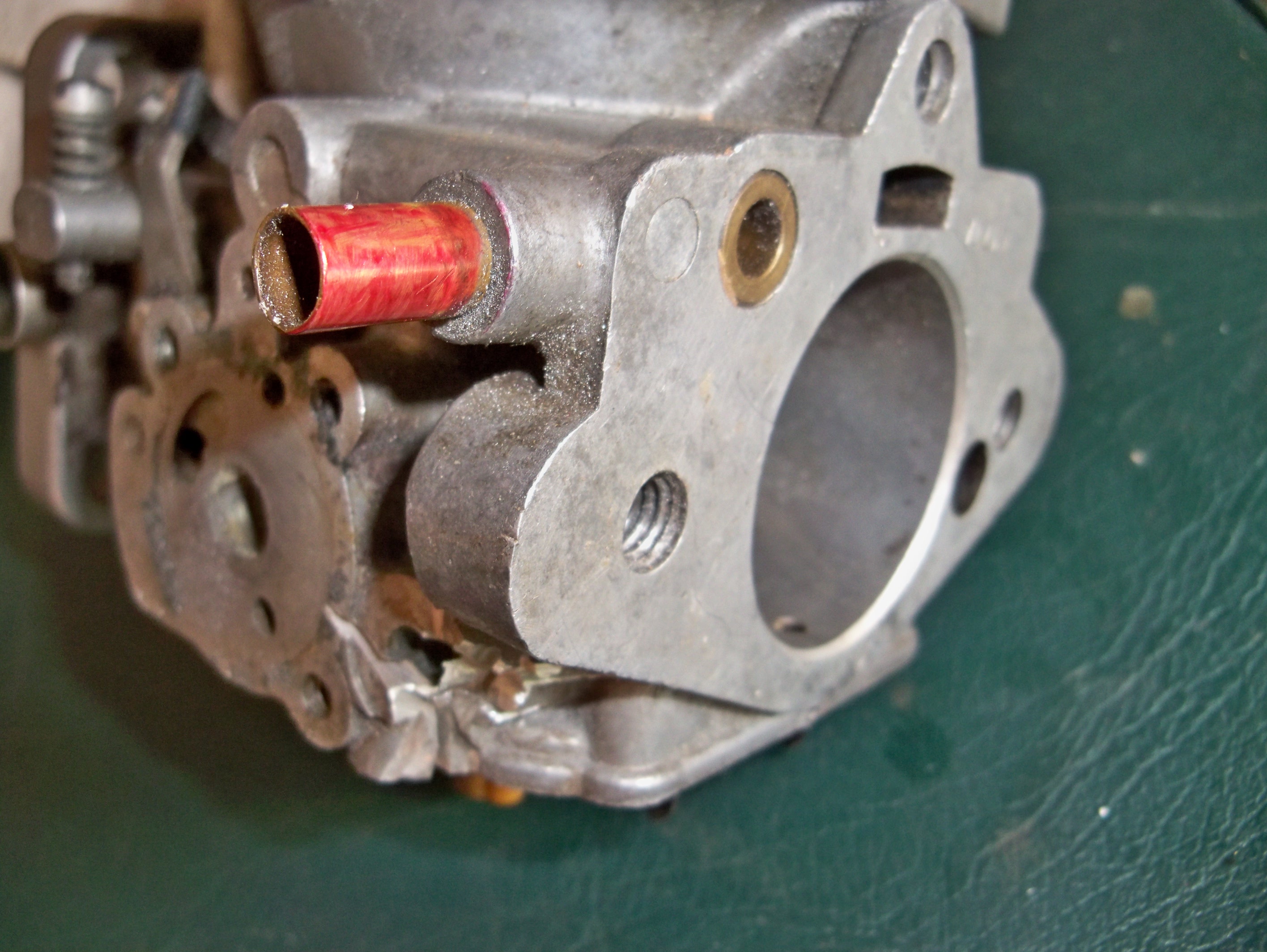

Do not cap or seal these nipples that I have colored 'red' unless you know how to disable the transition whereby all the float chamber ventilation is done thru the brass lined port in the carbs airbox mounting flange.

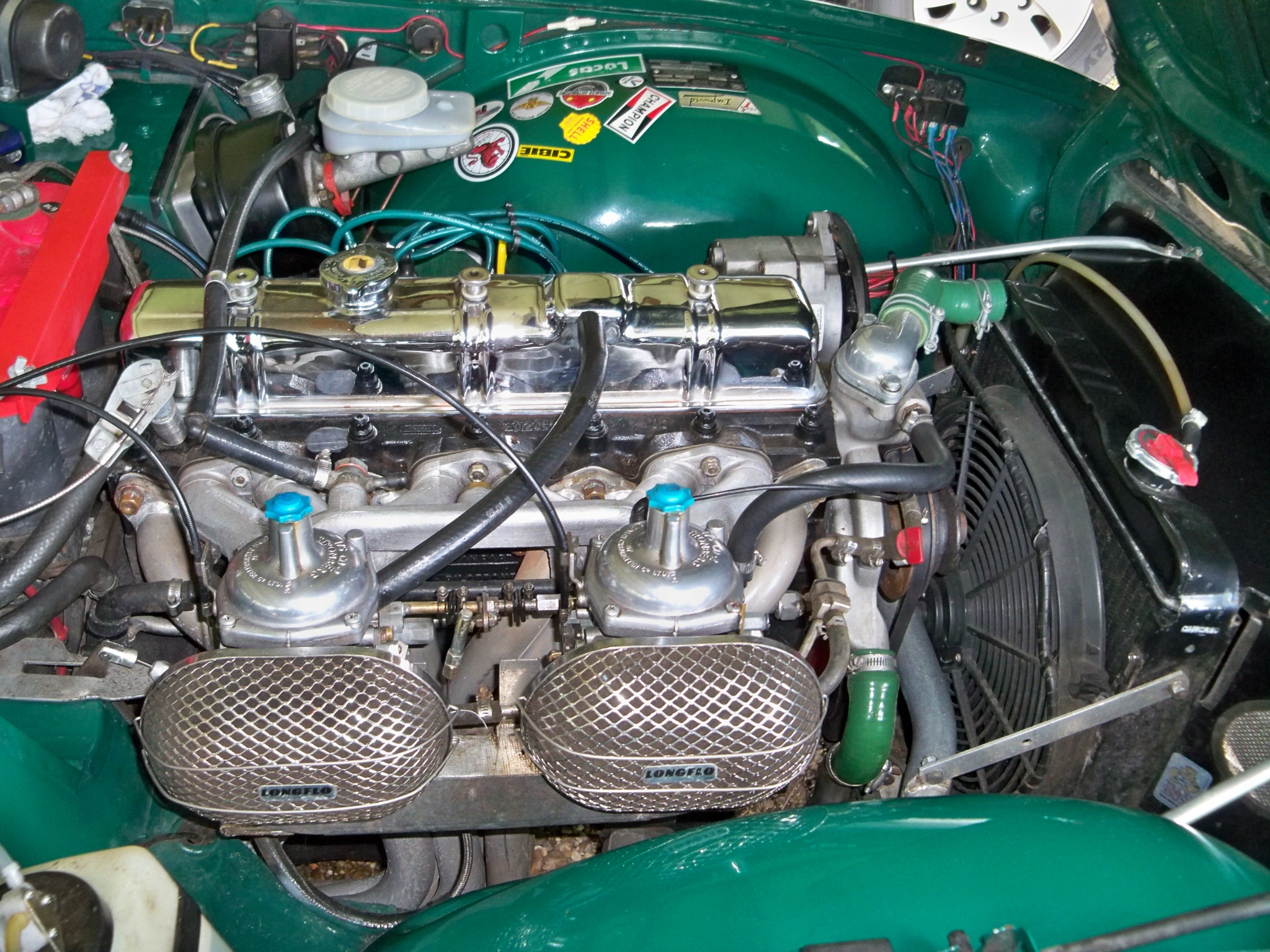

If you do eliminate the CC, I'd advise you to have the valve cover vent to the carbs evacuation ports.....It could be worth considering what's to become of the fuel tank vent line and the fumes it sometimes emits if you eliminate the CC.

I was able to eliminate a bunch of the emission stuff, but I didn't do it all at one time and I did experiment with alternatives

.

If you do eliminate the CC, I'd advise you to have the valve cover vent to the carbs evacuation ports.....It could be worth considering what's to become of the fuel tank vent line and the fumes it sometimes emits if you eliminate the CC.

I was able to eliminate a bunch of the emission stuff, but I didn't do it all at one time and I did experiment with alternatives

.

Last edited:

Thank you poolboy. It appears that your crankcase ventilation goes straight to the back carburetor only, and not the front carb, is that correct? Also, I'm not familiar with the modification to the float chamber vent. Is the addition of the brass port the modification? I'm not near the car at the moment to see if it has the brass port.

I was thinking about something similar for the fuel tank fumes. Thank you for the pictures!

I was thinking about something similar for the fuel tank fumes. Thank you for the pictures!

poolboy

Yoda

Offline

I was able to vent the valve cover to just one carb..but there was some mixture adjustments necessary to compensate...you may have to also unless you use both carbs

The brass line port is found on all post 72 carbs,,,,the hole is there on the other years just not brass lined as there is no transition valve on the pre 73 carbs..and no 'red nipple' vent.

The brass line port is found on all post 72 carbs,,,,the hole is there on the other years just not brass lined as there is no transition valve on the pre 73 carbs..and no 'red nipple' vent.

Okay, my 73 does indeed have the brass ports and a matching hole in the filter box. So am I safe in capping the fuel bowl vent ports (the red nipple in your picture)? I'm not sure about what the transition valve is or if I even have one..

*EDIT* I just read the technical article on Buckeye Triumphs website and now understand the transition valve. So, it seems fuel is only vented out the red nipple (to the CC) when the engine is off or at idle. I believe you were suggesting disabling the valve so that the fuel chamber always vents to the air filter assembly. Is there a procedure for that?

*EDIT* I just read the technical article on Buckeye Triumphs website and now understand the transition valve. So, it seems fuel is only vented out the red nipple (to the CC) when the engine is off or at idle. I believe you were suggesting disabling the valve so that the fuel chamber always vents to the air filter assembly. Is there a procedure for that?

Last edited:

poolboy

Yoda

Offline

Of course yo have a float chamber vent transition valve if you have 73 and later carbs... although the 73 versions were unique to that year....I wouldn't cap the red nipples until or unless you disable the transition and have the float chamber venting thru the brass line hole under all conditions including when the engine is idling.

poolboy

Yoda

Offline

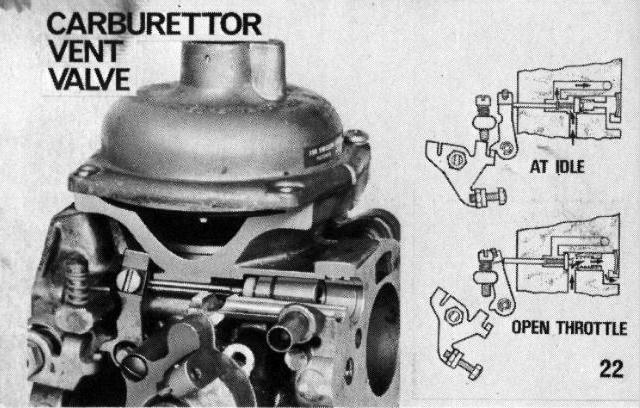

There are a few ways to disable the 73 and have them vent like the 70, 71 and 72 carbs solely thru the vent hole in the carbs air box mounting flange.

On the carbs I service, I do a permanent mod, but what you can do is remove the activation arm that the green pointer indicates and make sure the spring loaded brass plunger is fully extended...pretty much as far out as you see in my picture.

Stick something into the brass lined hole and push on the plunger to make sure it is fully extended. Then remove whatever you used to push the plunger

As long as the spring loeaded plunger stays extended all the venting idle included will be thru the brass lined hole.

On the carbs I service, I do a permanent mod, but what you can do is remove the activation arm that the green pointer indicates and make sure the spring loaded brass plunger is fully extended...pretty much as far out as you see in my picture.

Stick something into the brass lined hole and push on the plunger to make sure it is fully extended. Then remove whatever you used to push the plunger

As long as the spring loeaded plunger stays extended all the venting idle included will be thru the brass lined hole.