FrogPond

Freshman Member

Offline

Greetings first post and I have a question, I'm building a sidevalve special with a 100E engine, rear axle with brakes, radiator and front brakes (hopefully) on a dropped upright front axle & spindles. I would like to use the 100E's braking system pretty much intact.

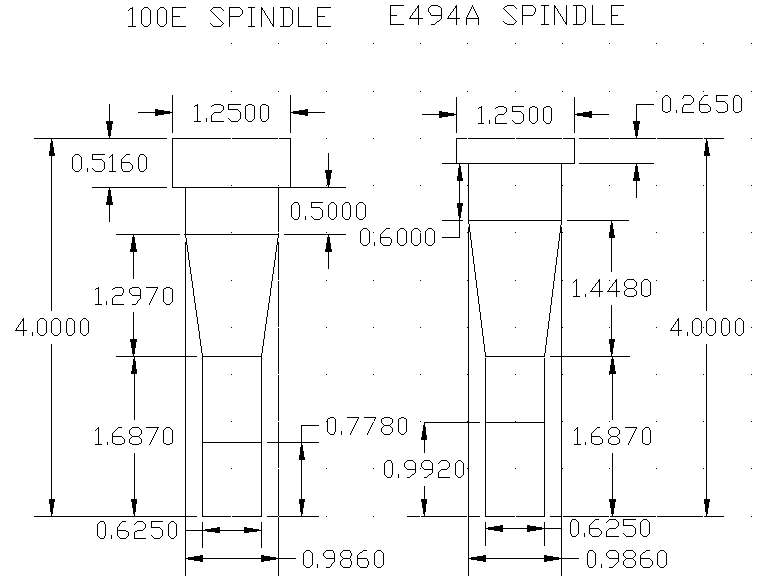

I have some upright spindles. Probably E494A from looking at pictures. I have a '57 100E donor car. I have taken the 100E front brakes apart and the spindles have all of the same diameters. I guess I have the earlier 100E spindle, a good thing. The hub goes right on. If you tighten the castle nut, the hub bottoms on the spindle before the nut gets tight. If I put a spacer between the spindle and inner bearing, the seal will be off of the upright's narrow seal boss (probably). I added a picture [Measured (some by eye) with a digital caliper. Don't build a spindle from these] I'm going to clean up a 100E hub and measure it soon.

I'm pretty sure I'm covering well trodden ground. Is there a write-up somewhere ? Once I get the hub/drum on, I can figure out where the backing plate needs to be. I can probably make the big hole and re-drill the backing plates to fit the upright spindles. I'm wondering what the spacing should look like. Any pointers would be greatly appreciated. Thanks, Mike

I have some upright spindles. Probably E494A from looking at pictures. I have a '57 100E donor car. I have taken the 100E front brakes apart and the spindles have all of the same diameters. I guess I have the earlier 100E spindle, a good thing. The hub goes right on. If you tighten the castle nut, the hub bottoms on the spindle before the nut gets tight. If I put a spacer between the spindle and inner bearing, the seal will be off of the upright's narrow seal boss (probably). I added a picture [Measured (some by eye) with a digital caliper. Don't build a spindle from these] I'm going to clean up a 100E hub and measure it soon.

I'm pretty sure I'm covering well trodden ground. Is there a write-up somewhere ? Once I get the hub/drum on, I can figure out where the backing plate needs to be. I can probably make the big hole and re-drill the backing plates to fit the upright spindles. I'm wondering what the spacing should look like. Any pointers would be greatly appreciated. Thanks, Mike

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>