Hi Cmac,

Bob beat me to the punch in answering your question.

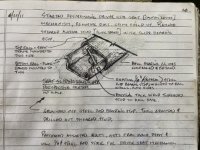

Maybe to provide an aid in the form of a visual, I did a record sketch when I had my first Healey. I too, was in need of refurbishing both seat slider mechanisms. The ball bearings were complete and fine on mine. And one of my, what I call a, "Tack Weld Threaded Stud," on the driver side had sheared away from the floor pan from perhaps, over tightening at the factory, resulting from having inadequate structural stability of the seat secured to the floor, making it unsafe (Oh, like that really matters in a Healey?).

Anyway, from the sketch enclosed, you can see there is this 1/8" diameter rod (Bob referred to as a pin and I came up with my own concoction term as a, "Bearing Stop"), that was in the way of conveniently removing the one defective stud. Again and as a "ditto" to Bob's answer, that 1/8" diameter rod does help in preventing the bearings from rolling out found in between the top and bottom rail. It was necessary for me to completely cut away the pin/stop to gain convenient access and begin completely removing the defective stud from the bottom rail.

From my notes, you can see I had to purchase a new piece of 1/8" diameter steel rod (stock). Then place bearings back in between the rails, then cut to slide new piece of rod through the existing side holes of the lower slide rail, then solder/weld.

As a word of advice, one should make sure to extend the rod just enough outside the inner rail to prevent the bearings having any opportunity of slipping out. But by the same token, make sure the rod overall length does not come in contact with the outer rail's motion, thus preventing potential binding (overall length of rod as my sketch begins to suggests).

Hope the above helps in some way,

Paul

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>