Hi all

I started my BT7 today and the Ignition Warning Light stayed on. I had some intermittent issues with the Warning Light sometimes staying over the last few moths.

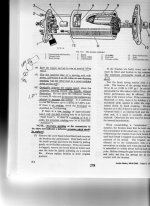

I checked the =dynamo output by disconnecting the D and F leads, bridging the two terminals with a jumper wire and checking the output voltage, which was less that 0.5 volts. According to the Bentley manual this suggests a problem with the "field winding".

I have a pair of new brushes in my spare box. Is it worth trying to see if replacing the brushes makes any difference or is the dynamo shot?

Can the brushes be replaced without having to remove the fan/pulley (looks like a tricky job to me)?

Otherwise my only option might be to buy a new dynamo.

Thanks in advance.

Phil

I started my BT7 today and the Ignition Warning Light stayed on. I had some intermittent issues with the Warning Light sometimes staying over the last few moths.

I checked the =dynamo output by disconnecting the D and F leads, bridging the two terminals with a jumper wire and checking the output voltage, which was less that 0.5 volts. According to the Bentley manual this suggests a problem with the "field winding".

I have a pair of new brushes in my spare box. Is it worth trying to see if replacing the brushes makes any difference or is the dynamo shot?

Can the brushes be replaced without having to remove the fan/pulley (looks like a tricky job to me)?

Otherwise my only option might be to buy a new dynamo.

Thanks in advance.

Phil

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>