Please note that these photos may be copied and you can run them in your own photo viewer so as to see the detail better. If you need more detail, send me an email and I will send you a copy of the original.

The difficulty in determining authenticity and settling on just what it means for a piece to be "correct."

I believe that some owners either forget or are simply not aware of the fact that virtually all mass produced items have production changes, supercessions, and simple substitutions from time to time during the course of a production run. This can be confusing and frustrating for an owner of a car that is at least 25 years distant from the memory of what went on where and when it was built.

I can't conceive that MG or any other car maker did much differently. Most owners, and "purists" especially, just want the darned part to look the same, work the same, and make their car run the same, even if, sometimes, progress has changed how things are made or suppliers changed and that "better" might be slightly different. Expediency on the part of any manufacturer to keep units flowing out the door of the showrooms certainly could make a documentation process like putting our fist into a tar baby, I guess, but I think that at least a little direction would be helpful, even if all it does is give the majority of owners sufficient guidance and warning to keep from doing anything too foolish or to assume too much. I think that it is not always in our best interests to be too absolutist about parts, particularly at this late date. For concours cars, as close to the "truth", originality, is paramount, and probably always will be. Guide books, such as "Original MGB", are helpful, but not exhaustive in their coverage of the variety of parts used or how they were installed. Ask any judge at any event and they will probably tell you that they look for as best a rendition of the original intent as possible. But most also recognize that production variations play a part during any period of production and many of those changes or substitutions are not always well documented.

For the rest of us who use originality as a simple guidepost as to how things were originally intended to be, not necessarily how things will always stay, it would seem to me that functionality and quality of manufacture and materials might be at least equally important criteria in keeping our cars on the road. JMHO

* * * * * * * * * * * * * * * * * * * * * * * * * * * * * *

MGB rear Bumper differences ...

From Right to left:OE bumper, NEW Moss bumper (2005), and previously offered bumper (2000). Note the differences in the shapes of the ends. Neither of the aftermarket bumpers look quite like the OE bumper.

The fit of the most recent bumper offered is not quite right either. It is a bit short, leading me to speculate that all that was done to reshape the ends, was to fold over the end of the previously offered bumper, shortening its reach, and not quite getting the end shape right. However, if this is indeed what was done, I would think it was done to appease critical owners and yet not spend too much on retooling the dies for stamping the bumpers. At this point in the life of our classics, Retooling costs and additional steps in forming things can add considerable cost to the production of a part and could be a possible factor in a company choosing NOT to produce it at all. If they cannot regain what they have spent to make a part in the market place, it is simply not reasonable to expect any group to sell at a loss just for our convenience.

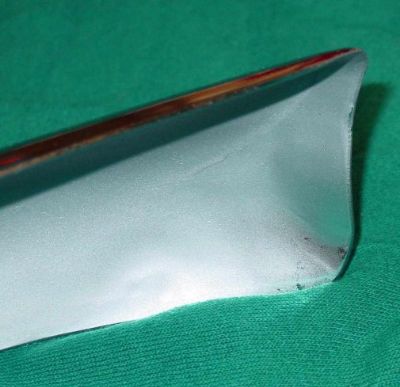

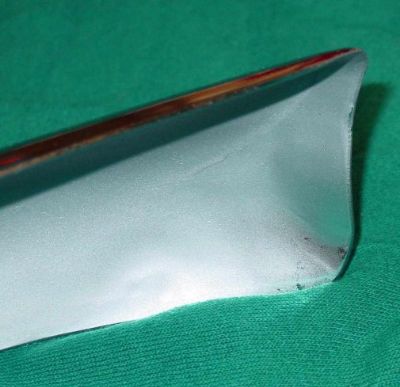

A shot of the inside of a new bumper end. You can see that it is a bit different from the original.

Finally, a shot of the outside of the new bumper end. There is a curved line to the end of the new folded part, whereas the OE style has a straight line. This too points to using the previous dies and cutoff of the bumper metal and simply folding them over without consideration to replicating the dimensions and amount of material needed to make a truly accurate reproduction. I would call this a "20 footer" replacement. ;-)

A Very Early "OEM" Bumper ~ photo courtesy of Peter Caldwell

You can see the difference in this bumper's shape of its end foldover compared to all of the above bumpers and those shown below, indicating to me the possibility that the shape of the ends and possibly the body of the bumper changed over time as a factory specification. This OE replacement bumper is still wrapped in its protective paper and the surface coated with a protectant, perhaps cosmoline. You can see the difference in this bumper's shape of its end foldover compared to all of the above bumpers and those shown below, indicating to me the possibility that the shape of the ends and possibly the body of the bumper changed over time as a factory specification. This OE replacement bumper is still wrapped in its protective paper and the surface coated with a protectant, perhaps cosmoline.

Robert Gloyd's array of repro and OE bumpers

A repro bumper on Bob's 66 B GT A repro bumper on Bob's 66 B GT

Another shot of the repro bumper on his 66 BGT Another shot of the repro bumper on his 66 BGT

Final shot of BGT repro bumper. Final shot of BGT repro bumper.

A different repro bumper on Bob's 67 B roadster. This one reminds me of the OE bumper taken from my own GT (it looked like this but was too scratched and worn to use without having it rechromed. However, the shape seems to be what I have come to think of as the "Norm" of bumper shapes for the chrome bumpered MGBs, 1962-1974. A different repro bumper on Bob's 67 B roadster. This one reminds me of the OE bumper taken from my own GT (it looked like this but was too scratched and worn to use without having it rechromed. However, the shape seems to be what I have come to think of as the "Norm" of bumper shapes for the chrome bumpered MGBs, 1962-1974.

This is a shot of an actual OE bumper on Bob's 73 roadster. This one looks identical to the "OE" bumper on my GT, mentioned above. most of what I consider the defining feartures between this unit and the better repros are small details such as the way the ends are folded and shaped and the sharper shapes of the indentations for the mounting bolts. Overall shape seems to produce better and more consistent gaps between the bumper bar and the bodywork. JMO. This is a shot of an actual OE bumper on Bob's 73 roadster. This one looks identical to the "OE" bumper on my GT, mentioned above. most of what I consider the defining feartures between this unit and the better repros are small details such as the way the ends are folded and shaped and the sharper shapes of the indentations for the mounting bolts. Overall shape seems to produce better and more consistent gaps between the bumper bar and the bodywork. JMO.

* * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * *

Reproduction Grilles & Badges ~ what is in the current marketplace

Below are some photos of a grille I bought a few years ago. It is very much the same as a Tasker Metal Products grille I had bought back in 1988 and which still serves on my 68 MGBGT. It is not a bad grille, but according to persistent reports from owners of true OE grilles, these are different from the originals and neither fit nor look as the originals. That may be, but without authenticated photos of a genuine OE grille, the judgement is left up to you. Anyone who would like to post photos of a true OE grille here or elsewhere is invited to do so for everyone's edification.

A look at the rear of the grille, showing the chrome plated brass shell and the aluminum slat stamping. A look at the rear of the grille, showing the chrome plated brass shell and the aluminum slat stamping.

Looking at the bottom mountings for the repro grille. Looking at the bottom mountings for the repro grille.

Detail of badge plinth mounting to grille assembly. Detail of badge plinth mounting to grille assembly.

This is the badge supplied with the replacement grille above. It is a pretty poor imitation of the original. It appears to be a simple bit of foil printed with a too broadly penned silver logo. This is the badge supplied with the replacement grille above. It is a pretty poor imitation of the original. It appears to be a simple bit of foil printed with a too broadly penned silver logo.

This replacement badge, offered by British Auto Works, comes much closer to the original altho it too has its small shortcomings. At least its elements are raised as in the originals, and the silver trim gives the appearance of plating. However, even it's outlining is a bit too broad. Producing one like this costs a bit more to make and involves a more complicated process than used for the badge shown above. Still, a very nice piece in comparison to the badge offered above. This replacement badge, offered by British Auto Works, comes much closer to the original altho it too has its small shortcomings. At least its elements are raised as in the originals, and the silver trim gives the appearance of plating. However, even it's outlining is a bit too broad. Producing one like this costs a bit more to make and involves a more complicated process than used for the badge shown above. Still, a very nice piece in comparison to the badge offered above.

This is a true OE early MGB badge and plinth NOS condition. The owner has the original box to prove his claim. As you can see, it is slightly bowed and being as it is VERY early, it has the same type of "theater drape background" (my terminology) as used in the early horn buttons. You can just barely see this aspect of it in this photo. However, this background was banned by the British authorities shortly after the MGB's introduction because it had the unfortunate proclivity to act as a red reflector, a no-no on the front of any british car in the UK. This is a true OE early MGB badge and plinth NOS condition. The owner has the original box to prove his claim. As you can see, it is slightly bowed and being as it is VERY early, it has the same type of "theater drape background" (my terminology) as used in the early horn buttons. You can just barely see this aspect of it in this photo. However, this background was banned by the British authorities shortly after the MGB's introduction because it had the unfortunate proclivity to act as a red reflector, a no-no on the front of any british car in the UK.

This an image of another well used very early MGB grille badge which shows the "theater drape" background much more clearly. Again, note its similarity to the other early badge above vs. the others above it. This an image of another well used very early MGB grille badge which shows the "theater drape" background much more clearly. Again, note its similarity to the other early badge above vs. the others above it.

Another photo of a pristine NOS theater drape badge. Another photo of a pristine NOS theater drape badge.

If you look at this photo carefully, you can also see the impressions of the 4 rear locating pins cast into this plastic badge.

This is an overall shot of a VERY early grille slat assembly submitted by Al Mc Millan. This grille is NOT stamped sheet metal components as you will see in the next photo. This is an overall shot of a VERY early grille slat assembly submitted by Al Mc Millan. This grille is NOT stamped sheet metal components as you will see in the next photo.

In this close-up shot you can see that the slats are made from solid stock and shaped something like the leading edge of a wing. This was a lot more expensive to make and break. Probably one good reason why the next version (seen below) was, except for the badge plinth, entirely stamped metal. In this close-up shot you can see that the slats are made from solid stock and shaped something like the leading edge of a wing. This was a lot more expensive to make and break. Probably one good reason why the next version (seen below) was, except for the badge plinth, entirely stamped metal.

In this photo you can see the grille bars even better. In this photo you can see the grille bars even better.

Frontal view of the very early "theater drape" badge. Frontal view of the very early "theater drape" badge.

The back side of this badge. The back side of this badge.

You can clearly see the wavy grooves made to deliniate that "theater drape" background from the back side of this badge.

And its rather unusual mounting clamp (unusual to us at this point in time, at least). And its rather unusual mounting clamp (unusual to us at this point in time, at least).

If you take a look at this mounting and at the plinth it would rest in on the solid grille shown above, you can easily see that the center philips head screw was intended to mount through the hole in the rear of the plinth.

Stan Best's very nice roadster showing overall fit with front bonnet (better than mine with an aftermarket grille AND bonnet!) Stan Best's very nice roadster showing overall fit with front bonnet (better than mine with an aftermarket grille AND bonnet!)

Close up of the front logo plinth and grille slats. Note that they appear to be aluminum and also note the degree of depth there is within the plastic grille crest. Not too dissimilar to that of the better aftermarket badge shown above. Close up of the front logo plinth and grille slats. Note that they appear to be aluminum and also note the degree of depth there is within the plastic grille crest. Not too dissimilar to that of the better aftermarket badge shown above.

A rear view of the grille, showing the top of the grille shell, the top of the slat assembly, and the shape and probable metal used for the slats, which appear from this angle also to be aluminum. A rear view of the grille, showing the top of the grille shell, the top of the slat assembly, and the shape and probable metal used for the slats, which appear from this angle also to be aluminum.

Grille/fender fit. Also note that the shell has a slight flange extending at its rear from forming. Grille/fender fit. Also note that the shell has a slight flange extending at its rear from forming.

Fit on the RH side with the fender. Fit on the RH side with the fender.

|

You can see the difference in this bumper's shape of its end foldover compared to all of the above bumpers and those shown below, indicating to me the possibility that the shape of the ends and possibly the body of the bumper changed over time as a factory specification. This OE replacement bumper is still wrapped in its protective paper and the surface coated with a protectant, perhaps cosmoline.

You can see the difference in this bumper's shape of its end foldover compared to all of the above bumpers and those shown below, indicating to me the possibility that the shape of the ends and possibly the body of the bumper changed over time as a factory specification. This OE replacement bumper is still wrapped in its protective paper and the surface coated with a protectant, perhaps cosmoline.  A repro bumper on Bob's 66 B GT

A repro bumper on Bob's 66 B GT Another shot of the repro bumper on his 66 BGT

Another shot of the repro bumper on his 66 BGT Final shot of BGT repro bumper.

Final shot of BGT repro bumper. A different repro bumper on Bob's 67 B roadster. This one reminds me of the OE bumper taken from my own GT (it looked like this but was too scratched and worn to use without having it rechromed. However, the shape seems to be what I have come to think of as the "Norm" of bumper shapes for the chrome bumpered MGBs, 1962-1974.

A different repro bumper on Bob's 67 B roadster. This one reminds me of the OE bumper taken from my own GT (it looked like this but was too scratched and worn to use without having it rechromed. However, the shape seems to be what I have come to think of as the "Norm" of bumper shapes for the chrome bumpered MGBs, 1962-1974. This is a shot of an actual OE bumper on Bob's 73 roadster. This one looks identical to the "OE" bumper on my GT, mentioned above. most of what I consider the defining feartures between this unit and the better repros are small details such as the way the ends are folded and shaped and the sharper shapes of the indentations for the mounting bolts. Overall shape seems to produce better and more consistent gaps between the bumper bar and the bodywork. JMO.

This is a shot of an actual OE bumper on Bob's 73 roadster. This one looks identical to the "OE" bumper on my GT, mentioned above. most of what I consider the defining feartures between this unit and the better repros are small details such as the way the ends are folded and shaped and the sharper shapes of the indentations for the mounting bolts. Overall shape seems to produce better and more consistent gaps between the bumper bar and the bodywork. JMO.

A look at the rear of the grille, showing the chrome plated brass shell and the aluminum slat stamping.

A look at the rear of the grille, showing the chrome plated brass shell and the aluminum slat stamping. Looking at the bottom mountings for the repro grille.

Looking at the bottom mountings for the repro grille. Detail of badge plinth mounting to grille assembly.

Detail of badge plinth mounting to grille assembly. This is the badge supplied with the replacement grille above. It is a pretty poor imitation of the original. It appears to be a simple bit of foil printed with a too broadly penned silver logo.

This is the badge supplied with the replacement grille above. It is a pretty poor imitation of the original. It appears to be a simple bit of foil printed with a too broadly penned silver logo. This replacement badge, offered by British Auto Works, comes much closer to the original altho it too has its small shortcomings. At least its elements are raised as in the originals, and the silver trim gives the appearance of plating. However, even it's outlining is a bit too broad. Producing one like this costs a bit more to make and involves a more complicated process than used for the badge shown above. Still, a very nice piece in comparison to the badge offered above.

This replacement badge, offered by British Auto Works, comes much closer to the original altho it too has its small shortcomings. At least its elements are raised as in the originals, and the silver trim gives the appearance of plating. However, even it's outlining is a bit too broad. Producing one like this costs a bit more to make and involves a more complicated process than used for the badge shown above. Still, a very nice piece in comparison to the badge offered above.  This is a true OE early MGB badge and plinth NOS condition. The owner has the original box to prove his claim. As you can see, it is slightly bowed and being as it is VERY early, it has the same type of "theater drape background" (my terminology) as used in the early horn buttons. You can just barely see this aspect of it in this photo. However, this background was banned by the British authorities shortly after the MGB's introduction because it had the unfortunate proclivity to act as a red reflector, a no-no on the front of any british car in the UK.

This is a true OE early MGB badge and plinth NOS condition. The owner has the original box to prove his claim. As you can see, it is slightly bowed and being as it is VERY early, it has the same type of "theater drape background" (my terminology) as used in the early horn buttons. You can just barely see this aspect of it in this photo. However, this background was banned by the British authorities shortly after the MGB's introduction because it had the unfortunate proclivity to act as a red reflector, a no-no on the front of any british car in the UK.  This an image of another well used very early MGB grille badge which shows the "theater drape" background much more clearly. Again, note its similarity to the other early badge above vs. the others above it.

This an image of another well used very early MGB grille badge which shows the "theater drape" background much more clearly. Again, note its similarity to the other early badge above vs. the others above it.  Another photo of a pristine NOS theater drape badge.

Another photo of a pristine NOS theater drape badge.

This is an overall shot of a VERY early grille slat assembly submitted by Al Mc Millan. This grille is NOT stamped sheet metal components as you will see in the next photo.

This is an overall shot of a VERY early grille slat assembly submitted by Al Mc Millan. This grille is NOT stamped sheet metal components as you will see in the next photo. In this close-up shot you can see that the slats are made from solid stock and shaped something like the leading edge of a wing. This was a lot more expensive to make and break. Probably one good reason why the next version (seen below) was, except for the badge plinth, entirely stamped metal.

In this close-up shot you can see that the slats are made from solid stock and shaped something like the leading edge of a wing. This was a lot more expensive to make and break. Probably one good reason why the next version (seen below) was, except for the badge plinth, entirely stamped metal. In this photo you can see the grille bars even better.

In this photo you can see the grille bars even better.

Frontal view of the very early "theater drape" badge.

Frontal view of the very early "theater drape" badge.  The back side of this badge.

The back side of this badge. And its rather unusual mounting clamp (unusual to us at this point in time, at least).

And its rather unusual mounting clamp (unusual to us at this point in time, at least).

Stan Best's very nice roadster showing overall fit with front bonnet (better than mine with an aftermarket grille AND bonnet!)

Stan Best's very nice roadster showing overall fit with front bonnet (better than mine with an aftermarket grille AND bonnet!)  Close up of the front logo plinth and grille slats. Note that they appear to be aluminum and also note the degree of depth there is within the plastic grille crest. Not too dissimilar to that of the better aftermarket badge shown above.

Close up of the front logo plinth and grille slats. Note that they appear to be aluminum and also note the degree of depth there is within the plastic grille crest. Not too dissimilar to that of the better aftermarket badge shown above.  A rear view of the grille, showing the top of the grille shell, the top of the slat assembly, and the shape and probable metal used for the slats, which appear from this angle also to be aluminum.

A rear view of the grille, showing the top of the grille shell, the top of the slat assembly, and the shape and probable metal used for the slats, which appear from this angle also to be aluminum.  Grille/fender fit. Also note that the shell has a slight flange extending at its rear from forming.

Grille/fender fit. Also note that the shell has a slight flange extending at its rear from forming.  Fit on the RH side with the fender.

Fit on the RH side with the fender.