Offline

Dondel asked for help removing a transmission. Since I have done mine 3 times in three years, I'd like to supplement the workshop manual instructions with my own experience and lessons learned.

Assemble tools. All the bolts were 9/16" (trans bell housing) or 1/2" (mounts, clutch slave cylinder). I used a cheap air compressor and air wrench.

Gasoline was used to clean oil off of transmission after removal. Yes, mine leaks a lot.

Gasoline was used to clean oil off of transmission after removal. Yes, mine leaks a lot.

Remove seats.

I built a small bench to stabilize the transmission when lifting with the jack. It is 15" wide, 13" high and 9" deep

After jacking up the car about 15" I put jack stands under each of the two front suspension plates (under the springs) and each rear spring. The bench then fits under the transmission. If not, jack up the rear axle a little higher to get it in and then lower back on stands. Put a block of wood on a jack under the oil pan and jack up the engine just enough to support it (about 1/4" or less) when you remove the transmission. I use a basic scissors jack for this.

I have a side shift trans in a 1960 BN7, so removing the tunnel and the supplemental trans. cover are quite different than with the newer models with consoles. Once the tunnel cover(s) are off, start with disconnecting everything that connects with the transmission: not in any particular order -- overdrive solenoid wire, speedometer cable, drive shaft, clutch slave cylinder/ground strap, starter motor (I just remove bolts, pull it out a little and leave hanging).

The drive shaft can remain, but pushed to the side

Remove bolts holding rear transmission mount to chassis. I recommend replacing the rubber mounts with new ones if yours are soaked with oil and dissolving like mine were.

Remove the steady bracket and replace the rubber bushings with new ones or with poly bushings when you are ready to reinstall.

Start removing bolts from around bell housing. The ones on the bottom are easy because you can reach both nut and bolt at the same time.

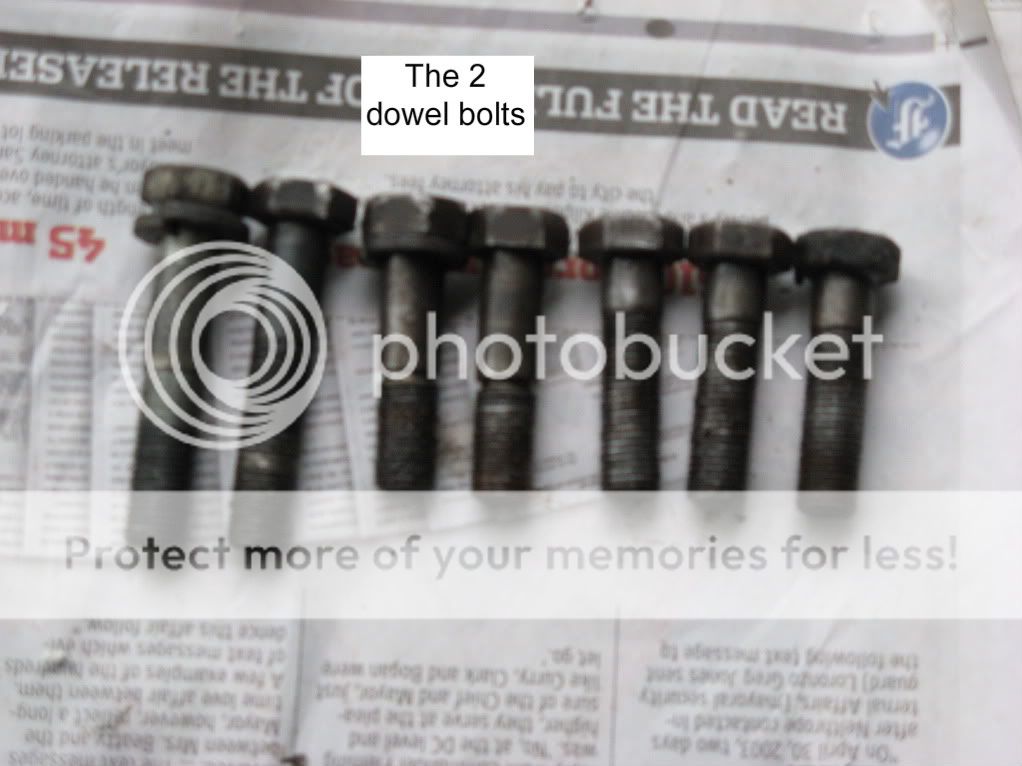

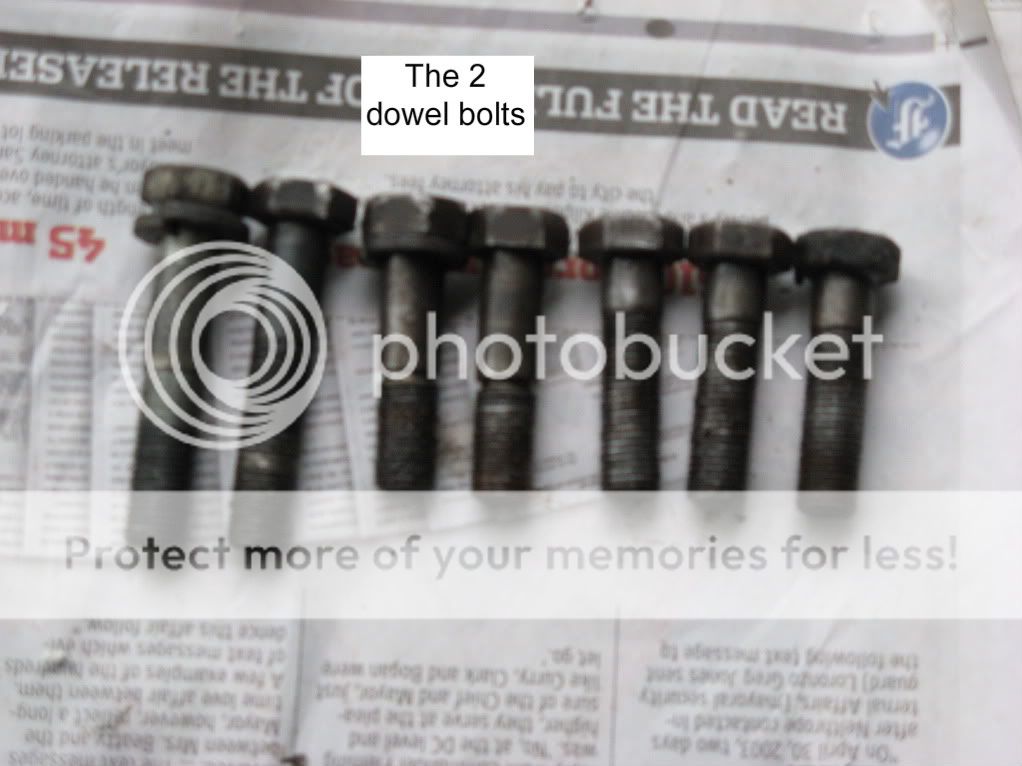

Now put a floor jack under the transmission (or under the bench if you are using one like mine) and put gentle support on the transmission. Remove the side bolts. I had to put a close-end wrench on the nut from the engine compartment and then remove the bolt from inside the car hoping the open-end wrench snugged up to the the engine block and didnt' fall off. If you have a helper it goes twice as fast. Same deal with the top bolts. The top bolt at 11:00 (upper left) is a dowel bolt and must go back in the same place to locate the transmission properly. There is another one in the bottom right (5:00 position)

Note the two longer bolts, I think they go into the engine block threaded holes without nuts. Just remember them when you remove them. With all the bolts removed and the transmission support on the jack, position youself at the back of the transmission sitting on the driveshaft tunnel straddling the transmission with your feet on the front panel. Lift on the rear of the transmission and pull back using your legs to push. You may have to use a screwdriver once you get a big enough crack to insert between engine plate and bell housing to free it up by a half inch or so. Then it should come out, the drive shaft may interfere somewhat, but work around it. I used a floor jack inserted from the rear so that the jack wheels would roll back with pulling the transmission backwards. Once free grab the bell housing and pull it to the passenger side.

Note the two longer bolts, I think they go into the engine block threaded holes without nuts. Just remember them when you remove them. With all the bolts removed and the transmission support on the jack, position youself at the back of the transmission sitting on the driveshaft tunnel straddling the transmission with your feet on the front panel. Lift on the rear of the transmission and pull back using your legs to push. You may have to use a screwdriver once you get a big enough crack to insert between engine plate and bell housing to free it up by a half inch or so. Then it should come out, the drive shaft may interfere somewhat, but work around it. I used a floor jack inserted from the rear so that the jack wheels would roll back with pulling the transmission backwards. Once free grab the bell housing and pull it to the passenger side.

The transmission with OD weighs about 130 lbs. but supporting one end with the car or the jack means you need lift much less weight. I did it with a weak back. I only needed my wife to get it completely out of the car.

Replacement is mostly the reverse of removal. The key is to get the transmission and engine in line. Getting the tranmssion shaft into the pilot bearing of the crankshaft may take a lot of wiggling and pushing. One of the three times I did it, I had to use a long 1/4" bolt in one of the bottom holes to draw the trans into position. The last time, I had an opening of about 1/4" to 1/2" at the top of the bell housing which I could see, but no amount of pushing would get it home. Finally I looked under the car and saw that the bottom of the bell housing was hitting the engine plate, but the engine/trans were too high. I lowered the jacks and it closed right up. So check the bottom gap periodically during your struggles. Don't forget tot reinstall the rear steady bracket and tighten it to keep the engine from shifting forward under heavy braking and causing the fan to tear up the radiator.

I'm going to stop here, but if you find this useful and want more info on replacing the clutch or installing a rear main lip seal, let me know.

Assemble tools. All the bolts were 9/16" (trans bell housing) or 1/2" (mounts, clutch slave cylinder). I used a cheap air compressor and air wrench.

Remove seats.

I built a small bench to stabilize the transmission when lifting with the jack. It is 15" wide, 13" high and 9" deep

After jacking up the car about 15" I put jack stands under each of the two front suspension plates (under the springs) and each rear spring. The bench then fits under the transmission. If not, jack up the rear axle a little higher to get it in and then lower back on stands. Put a block of wood on a jack under the oil pan and jack up the engine just enough to support it (about 1/4" or less) when you remove the transmission. I use a basic scissors jack for this.

I have a side shift trans in a 1960 BN7, so removing the tunnel and the supplemental trans. cover are quite different than with the newer models with consoles. Once the tunnel cover(s) are off, start with disconnecting everything that connects with the transmission: not in any particular order -- overdrive solenoid wire, speedometer cable, drive shaft, clutch slave cylinder/ground strap, starter motor (I just remove bolts, pull it out a little and leave hanging).

The drive shaft can remain, but pushed to the side

Remove bolts holding rear transmission mount to chassis. I recommend replacing the rubber mounts with new ones if yours are soaked with oil and dissolving like mine were.

Remove the steady bracket and replace the rubber bushings with new ones or with poly bushings when you are ready to reinstall.

Start removing bolts from around bell housing. The ones on the bottom are easy because you can reach both nut and bolt at the same time.

Now put a floor jack under the transmission (or under the bench if you are using one like mine) and put gentle support on the transmission. Remove the side bolts. I had to put a close-end wrench on the nut from the engine compartment and then remove the bolt from inside the car hoping the open-end wrench snugged up to the the engine block and didnt' fall off. If you have a helper it goes twice as fast. Same deal with the top bolts. The top bolt at 11:00 (upper left) is a dowel bolt and must go back in the same place to locate the transmission properly. There is another one in the bottom right (5:00 position)

The transmission with OD weighs about 130 lbs. but supporting one end with the car or the jack means you need lift much less weight. I did it with a weak back. I only needed my wife to get it completely out of the car.

Replacement is mostly the reverse of removal. The key is to get the transmission and engine in line. Getting the tranmssion shaft into the pilot bearing of the crankshaft may take a lot of wiggling and pushing. One of the three times I did it, I had to use a long 1/4" bolt in one of the bottom holes to draw the trans into position. The last time, I had an opening of about 1/4" to 1/2" at the top of the bell housing which I could see, but no amount of pushing would get it home. Finally I looked under the car and saw that the bottom of the bell housing was hitting the engine plate, but the engine/trans were too high. I lowered the jacks and it closed right up. So check the bottom gap periodically during your struggles. Don't forget tot reinstall the rear steady bracket and tighten it to keep the engine from shifting forward under heavy braking and causing the fan to tear up the radiator.

I'm going to stop here, but if you find this useful and want more info on replacing the clutch or installing a rear main lip seal, let me know.

Hey there Guest!

Hey there Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

A friendly reminder - be careful what links you click on here. If a link is posted by someone you don't know, or the URL looks fishy, DON'T CLICK. Spammers sometimes post links that lead to sites that can infect your computer, so be mindful what you click.

A friendly reminder - be careful what links you click on here. If a link is posted by someone you don't know, or the URL looks fishy, DON'T CLICK. Spammers sometimes post links that lead to sites that can infect your computer, so be mindful what you click.