I bought a pair of ebay floor pans for my bugeye. The welds along the rocker panels are easily accessible from inside the car while it is upright. At the tunnel joint I'm not certain since the 2 piece installation is not stock. Maybe I'll have to weld from below.

It also seems I'll have to remove the lower spring plates and maybe the springs. If the springs are out, how do I hold up the back end of the car while it is upright? The floor pan rusting is not too bad; the spring boxes should be OK.

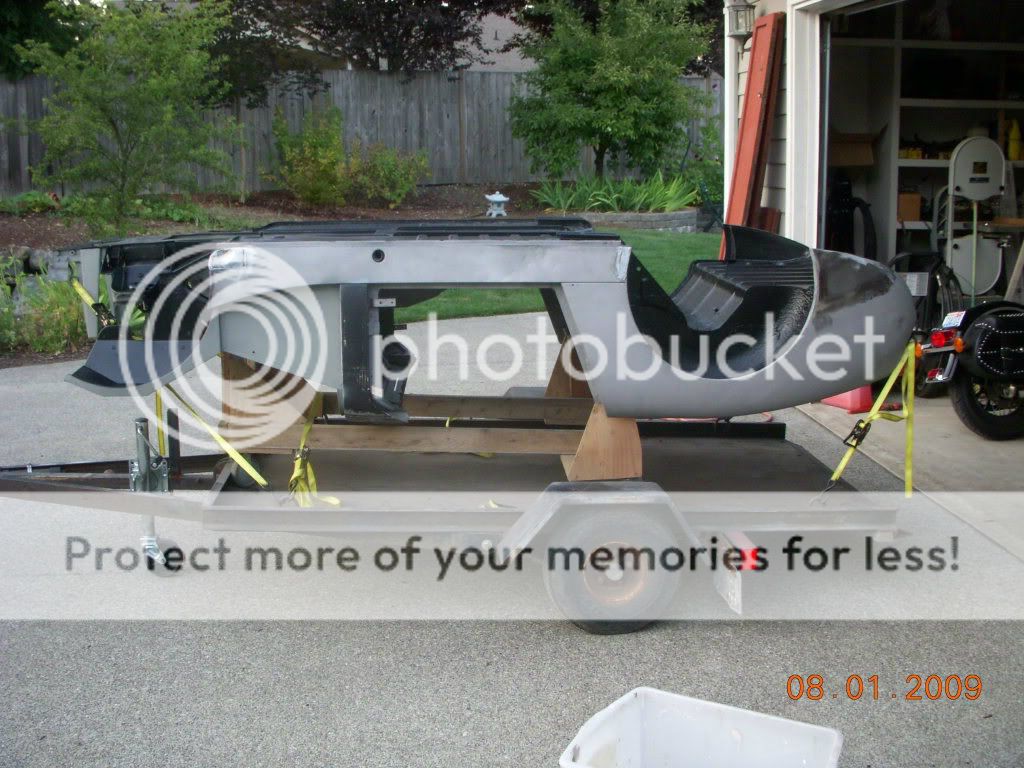

If there's a lot of welding from below is a rotisserie a better solution? Again, what's to hold up the back end -- are the bumperette brackets strong enough?

Thanks, Jim

It also seems I'll have to remove the lower spring plates and maybe the springs. If the springs are out, how do I hold up the back end of the car while it is upright? The floor pan rusting is not too bad; the spring boxes should be OK.

If there's a lot of welding from below is a rotisserie a better solution? Again, what's to hold up the back end -- are the bumperette brackets strong enough?

Thanks, Jim

Hey there Guest!

Hey there Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

A friendly reminder - be careful what links you click on here. If a link is posted by someone you don't know, or the URL looks fishy, DON'T CLICK. Spammers sometimes post links that lead to sites that can infect your computer, so be mindful what you click.

A friendly reminder - be careful what links you click on here. If a link is posted by someone you don't know, or the URL looks fishy, DON'T CLICK. Spammers sometimes post links that lead to sites that can infect your computer, so be mindful what you click.