T

Tinster

Guest

Guest

Offline

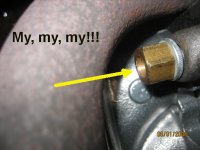

This post from Bill is for sure worth repeating since

it looks like several folks are going to be installing

refurbished carbs. Lesson Photo attached-

I am crying in my coffee cup!! Bill wrote:

"Dale,

One thing is don't use brass nuts . These are commonly used on exhaust flanges because the brass seems to break away from the iron studs when needed after lots of heat and rust over time. Brass nuts are thick because they are brass and not that strong. Use only high quality steel nuts of the same grade as the studs. The studs that come with the head of the TR6 are just so long, certainly not long enough to hold a thick brass nut, and lock washer. Juat like putting a tire on the car, you tend to torque them down by hand, just knowing how much hand torque is enough. The manifold studs are the same, suck 'em down by feel, then re-"torque" them after running a while.

it looks like several folks are going to be installing

refurbished carbs. Lesson Photo attached-

I am crying in my coffee cup!! Bill wrote:

"Dale,

One thing is don't use brass nuts . These are commonly used on exhaust flanges because the brass seems to break away from the iron studs when needed after lots of heat and rust over time. Brass nuts are thick because they are brass and not that strong. Use only high quality steel nuts of the same grade as the studs. The studs that come with the head of the TR6 are just so long, certainly not long enough to hold a thick brass nut, and lock washer. Juat like putting a tire on the car, you tend to torque them down by hand, just knowing how much hand torque is enough. The manifold studs are the same, suck 'em down by feel, then re-"torque" them after running a while.

Hey there Guest!

Hey there Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

A friendly reminder - be careful what links you click on here. If a link is posted by someone you don't know, or the URL looks fishy, DON'T CLICK. Spammers sometimes post links that lead to sites that can infect your computer, so be mindful what you click.

A friendly reminder - be careful what links you click on here. If a link is posted by someone you don't know, or the URL looks fishy, DON'T CLICK. Spammers sometimes post links that lead to sites that can infect your computer, so be mindful what you click.