RobSelina

Jedi Warrior

Offline

I want to go tube shocks in the rear. I like the change it made up front.

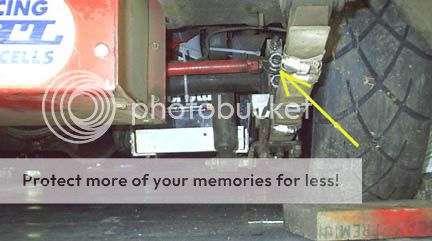

I'm looking at using the existing mounting hole on the chassis where the rubber retaining strap is attached. At the axle, I'm thinking I'll use the stock shock mounting point on the spring backing plate.

At rest, there's roughly 11" between these two points. A quick look at the Monroe website makes me think the Monroe Sensatrac model #5893 may work out. It's got 1/2" and 5/8" eyes (top and bottom respectively), compressed length of 9.375" and extended length 14.250" Total travel of 4.875"....

The top mount hole I'm considering is only a 3/8" diameter hole, so I'd have to run a sleeve, but does this look feasible? How have others done this? Is that top mounting hole I'm considering strong enough?

It looks like I'll have to get my exhaust rebent to clear the shock, but is there anything else I've forgotten?

BTW - I suspect this mounting system is what moss uses on their low-end tube shock conversion kit:

https://www.mossmotors.com/Shop/ViewProducts.aspx?PlateIndexID=52209

Thanks! /ubbthreads/images/graemlins/cheers.gif

I'm looking at using the existing mounting hole on the chassis where the rubber retaining strap is attached. At the axle, I'm thinking I'll use the stock shock mounting point on the spring backing plate.

At rest, there's roughly 11" between these two points. A quick look at the Monroe website makes me think the Monroe Sensatrac model #5893 may work out. It's got 1/2" and 5/8" eyes (top and bottom respectively), compressed length of 9.375" and extended length 14.250" Total travel of 4.875"....

The top mount hole I'm considering is only a 3/8" diameter hole, so I'd have to run a sleeve, but does this look feasible? How have others done this? Is that top mounting hole I'm considering strong enough?

It looks like I'll have to get my exhaust rebent to clear the shock, but is there anything else I've forgotten?

BTW - I suspect this mounting system is what moss uses on their low-end tube shock conversion kit:

https://www.mossmotors.com/Shop/ViewProducts.aspx?PlateIndexID=52209

Thanks! /ubbthreads/images/graemlins/cheers.gif

Hey there Guest!

Hey there Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

A friendly reminder - be careful what links you click on here. If a link is posted by someone you don't know, or the URL looks fishy, DON'T CLICK. Spammers sometimes post links that lead to sites that can infect your computer, so be mindful what you click.

A friendly reminder - be careful what links you click on here. If a link is posted by someone you don't know, or the URL looks fishy, DON'T CLICK. Spammers sometimes post links that lead to sites that can infect your computer, so be mindful what you click.