CJD

Yoda

Offline

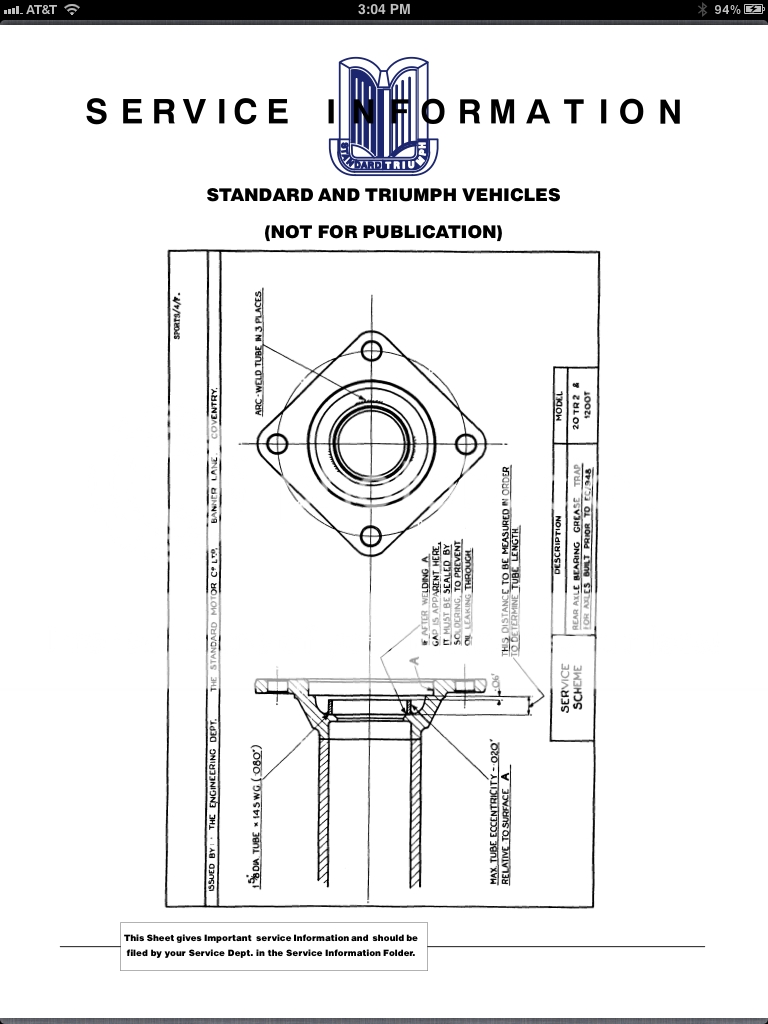

OK, got the Jag running, got Xmas out of the way...so I am finally getting back to the TR2 basket case. First question about the lockheed axle...

The Girling axle had grease seals inside the outer bearings. Looking in this axle, I cannot tell what I am looking at, but they are definitely not traditional seals. It is about 1" of bare metal and an outer cup around the inside edge to hold grease. Is this all these axles use for grease seals? It appears if you over grease the bearings it'll just squeeze into the axle tube, but I guess that would work?!? Looking at them, I do not think they can be tapped out easily, and I'm not sure they would need to be tapped out.

Anyway...any insight would be appreciated. Once I get rolling, I'll post the pics, as usual.

The Girling axle had grease seals inside the outer bearings. Looking in this axle, I cannot tell what I am looking at, but they are definitely not traditional seals. It is about 1" of bare metal and an outer cup around the inside edge to hold grease. Is this all these axles use for grease seals? It appears if you over grease the bearings it'll just squeeze into the axle tube, but I guess that would work?!? Looking at them, I do not think they can be tapped out easily, and I'm not sure they would need to be tapped out.

Anyway...any insight would be appreciated. Once I get rolling, I'll post the pics, as usual.

Hey there Guest!

Hey there Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

A friendly reminder - be careful what links you click on here. If a link is posted by someone you don't know, or the URL looks fishy, DON'T CLICK. Spammers sometimes post links that lead to sites that can infect your computer, so be mindful what you click.

A friendly reminder - be careful what links you click on here. If a link is posted by someone you don't know, or the URL looks fishy, DON'T CLICK. Spammers sometimes post links that lead to sites that can infect your computer, so be mindful what you click.