Drew, on the flywheel, look where the clutch rides on the fylwheel, can you feel grooves with a fingernail, if so, it need to resurfaced, heat spots like Bob said would also be a good reason to resurface the flywheel, it is reasonably smooth, has no bad discoloration, then you can skip this, next thing to pay close attention to on the flywheel is the the starter ring gear, if you see wear, replace it, both of these, for the most part, will be performed by a machine shop for you.

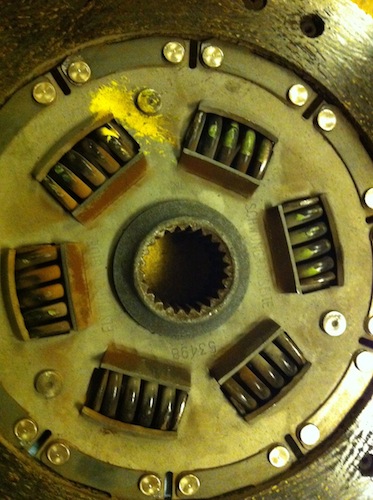

On the clutch, on the disc you can look at the wear of the friction material, in realationship to the rivets which attach it to the metal disc. On a pressure plate you look for wear on the button where the throw-out bearing makes conrtact, and the friction surface where the clutch disc rides. For the most part unless a clutch were to look brand new, you would never chance putting a questionable clutch back into a engine, because the work needing to happen to later replace it, far outweighs any savings you would have, much better to go with a new quality clutch.

FWIW, Drew I think you are a good canidate for doing this, the key is wanting to learn , and looking forward to the learning process. This is why I started my engine rebuilding kits with free tech advice , I know it sounds like a advertisment for my busness, but if money were all it this was about, I for sure would be doing something else other than building MG engines

I think for me it comes down to what you do with what you have learned, I could hold it tight to chest, or I could try to share it with MG community, I choose the latter. There so many little things to engine build that are not covered in a manual, and then there is sequence, and going to the machine shop, people just don't to this often enough to cover all the bases. I had to build alot of MG engines, before I came up with a "system" so to speak, doing this alot of times makes it alot easier, but that's not something most in the hobby regardless if they own mutilpe cars will ever do, heck it not even something a professional repair shop does alot, this is why I don't work on customer cars, I didn't want to be a mechanic, I wanted to be a engine rebuilder. Parts and their quailty are a biggie in rebuilding MG engines, there are bascilly two trains of though in the vendors's minds as for selling MG engine parts, if a choice is even offered, one beaing cheap, which can be good quailty, but often is not, or higher quailty, which normally is better quailty, but cost a little more. In some cases like for example, really high quailty camsahfts and lifters, good quailty can cost a good bit more, but this is a good place to spend extra money on, becasue these items due to thier qauilty, or lack of, are the ones that wil fail prematurely. I like the tech advice part of the engine kit , I like helping people do this job right, and often wonder why some customers don't ask for more help, and advice than they do. Alot of time a tech call is confirmation, and other times I literally, over the phone, walk someone thru something , for example cam timing. It is very rewarding to help someone get to the point where they understand a given process, and be able to carry it out.

In the car repair world,it always been the same deal, us vs them, mechanics/rebuilders vs part vendors, this is as old as the car itself, the two always have inner battle going on, and for the most part one doesn't understand the other's job. For example a mechanic, may not underastand what parts are available, and the part vendor is not a end user, so he sells something he may not ever have work with. Thats what I try to elminate with my kits, a end user, who know what parts are available, good or bad.

In short, call me, if you get to a point where you have a question, I think I gave you my cell number, so even Saturdays are ok , if you don't have me cell number, PM me, and I'll give it to you.

Hey there Guest!

Hey there Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

A friendly reminder - be careful what links you click on here. If a link is posted by someone you don't know, or the URL looks fishy, DON'T CLICK. Spammers sometimes post links that lead to sites that can infect your computer, so be mindful what you click.

A friendly reminder - be careful what links you click on here. If a link is posted by someone you don't know, or the URL looks fishy, DON'T CLICK. Spammers sometimes post links that lead to sites that can infect your computer, so be mindful what you click.