-

The Roadster Factory Recovery Fund - Friends, as you may have heard, The Roadster Factory, a respected British Car Parts business in PA, suffered a total loss in a fire on Christmas Day. Read about it, discuss or ask questions >> HERE. The Triumph Register of America is sponsoring a fund raiser to help TRF get back on their feet. If you can help, vist >> their GoFundMe page.

-

Hey there Guest!

Hey there Guest!

If you enjoy BCF and find our forum a useful resource, if you appreciate not having ads pop up all over the place and you want to ensure we can stay online - Please consider supporting with an "optional" low-cost annual subscription.**Upgrade Now**

(PS: Subscribers don't see this UGLY banner)

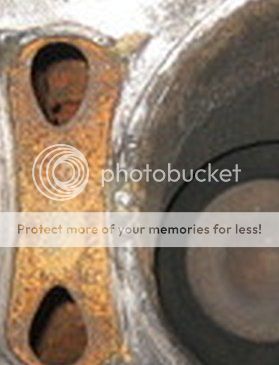

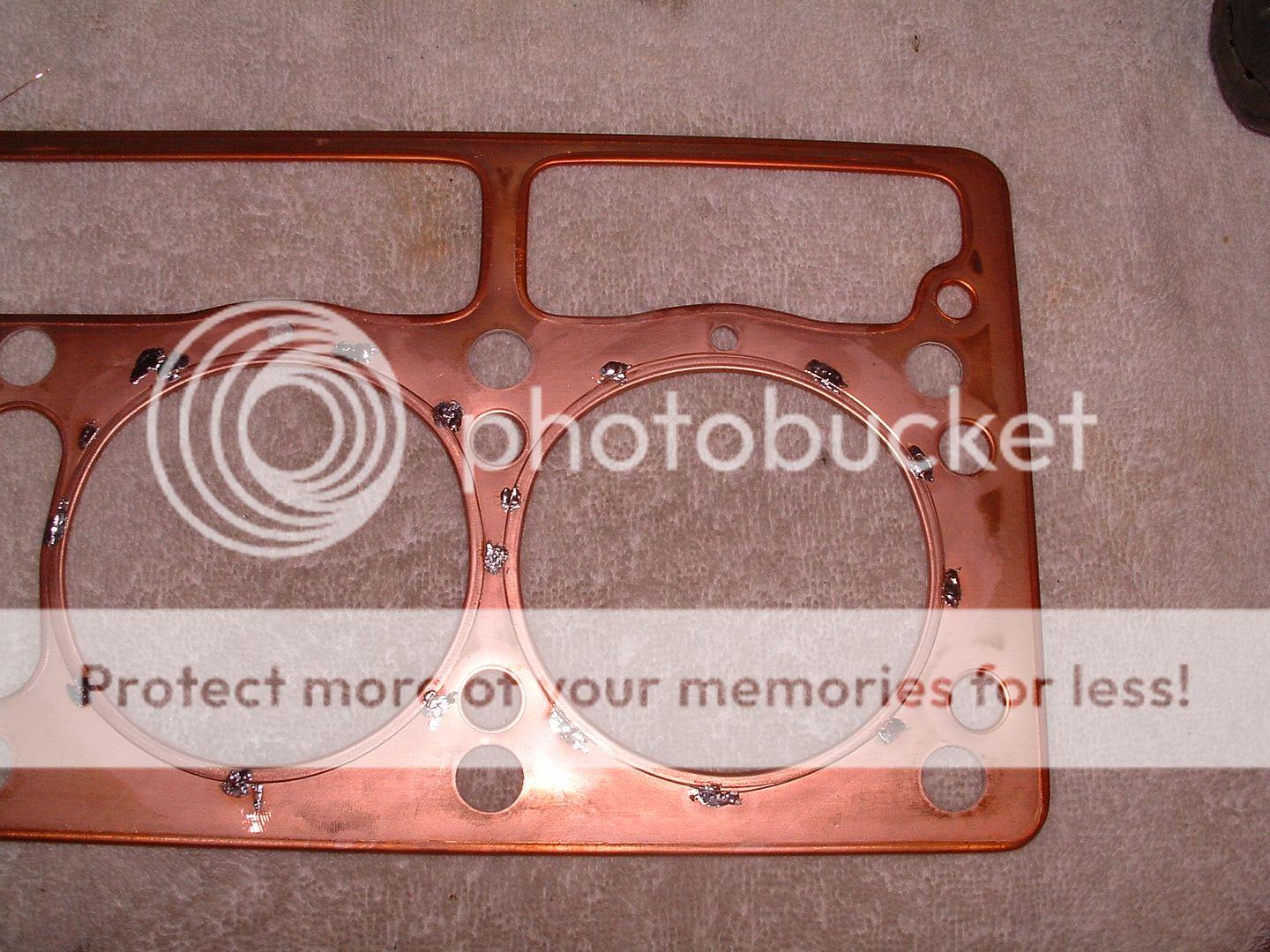

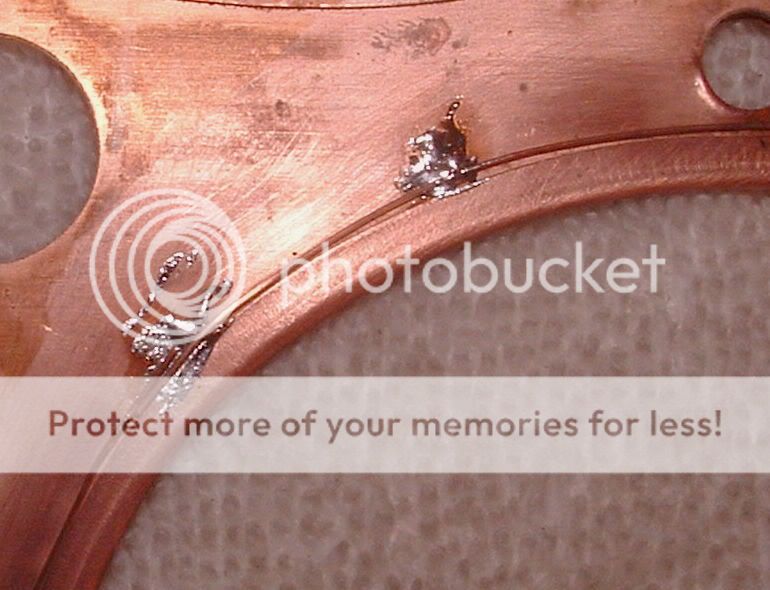

Head is off

- Thread starter sail

- Start date

Share this page

Similar threads

Similar threads

-

TR4/4A Does the water pump need to come off to remove the cylinder head?

- Started by tdskip

- Replies: 5

-

-

TR4/4A TR4A Head off for broken manifold stud - What else to do ?

- Started by blhazzard

- Replies: 13

-

-

-

-

-

-

-

-

-

-

-

G

-

-

-

-

TR2/3/3A Update on the head gasket repair......something is not right/

- Started by karls59tr

- Replies: 5

-

TR2/3/3A New head gasket is installed.....did a compression check motor cold.

- Started by karls59tr

- Replies: 4

-

-

-

-

TR2/3/3A Applying the Permatex copper gasket spray to the head gasket?

- Started by karls59tr

- Replies: 6

-

-

-

-

TR2/3/3A Retorquing the Cylinder Head after the initial torquing.?

- Started by karls59tr

- Replies: 23

-

-

-

-

-

TR2/3/3A Checking a cylinder head with a straight edge to see if it's warped?

- Started by karls59tr

- Replies: 22

-

-

-

-

-

-

-

-

-

-

-

-

-

TR6 Gp 2 cam, head shaved ,shorter pushrods, with a rough idle

- Started by DennisT

- Replies: 10

-

TR2/3/3A Who sells steering wheel control head "Allen head'' grub screws?

- Started by karls59tr

- Replies: 5

-

-

-

-

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

A friendly reminder - be careful what links you click on here. If a link is posted by someone you don't know, or the URL looks fishy, DON'T CLICK. Spammers sometimes post links that lead to sites that can infect your computer, so be mindful what you click.

A friendly reminder - be careful what links you click on here. If a link is posted by someone you don't know, or the URL looks fishy, DON'T CLICK. Spammers sometimes post links that lead to sites that can infect your computer, so be mindful what you click.