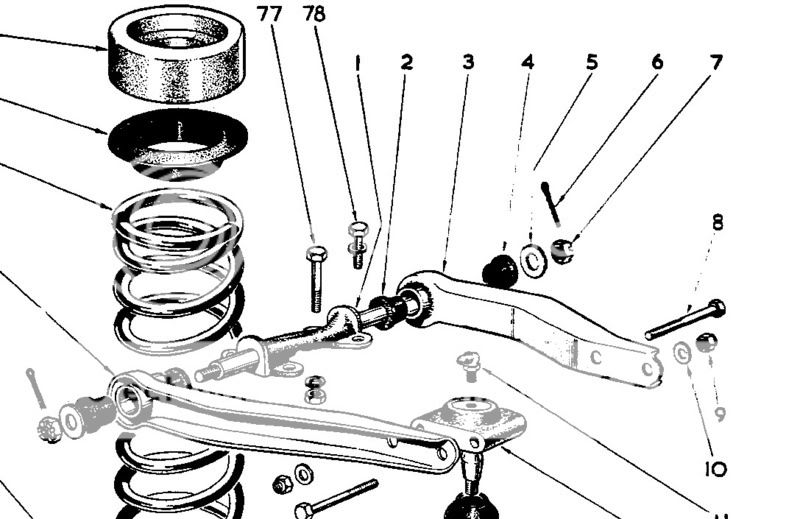

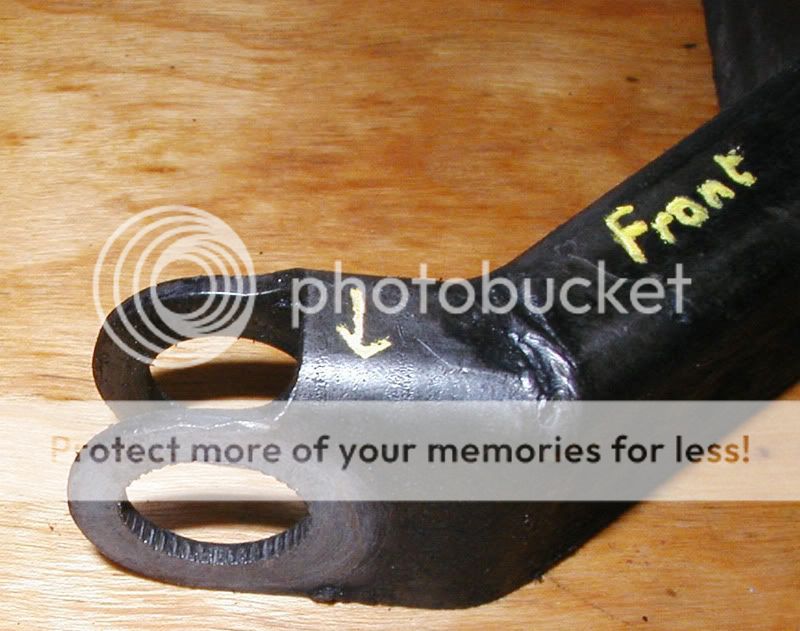

The diagram above is for a later TR4-4A (with 3 degrees caster); the TR3 uses the same zero caster wishbones as the TR2 (although some later ones were apparently reinforced for more strength).

But in either case, there actually isn't any tension from the spring, assuming your rebound stops are in good shape. I've done the upper bushings numerous times without touching the spring.

With the earlier style wishbones, if your rebound stops have sagged a bit, the end of the ball joint may touch the spring tower where it protrudes through the wishbones, making it difficult to remove that nut. If so, just stick a jack & chunk of 2x4 under the spring pan, just inboard of the trunnion, and lift it up a bit. As long as you don't jack against the trunnion itself, there still won't be any force on the upper wishbones.

I eventually got tired of having to replace those dang rubber bushings every few years, and converted to Nylatron. You might want to consider that, or polyurethane. It's possible that current supply rubber bushings last longer, but the ones I got in the 80s & 90s sure didn't last. In one case, I could see one of them starting to split less than a month after it was installed !

Don't forget that if you stick with rubber bushings, the suspension should be loaded when you tighten the nuts. The 2x4 under the spring pan works for that, too.

Hey there Guest!

Hey there Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

A friendly reminder - be careful what links you click on here. If a link is posted by someone you don't know, or the URL looks fishy, DON'T CLICK. Spammers sometimes post links that lead to sites that can infect your computer, so be mindful what you click.

A friendly reminder - be careful what links you click on here. If a link is posted by someone you don't know, or the URL looks fishy, DON'T CLICK. Spammers sometimes post links that lead to sites that can infect your computer, so be mindful what you click.