T

Tinster

Guest

Guest

Offline

This non-mechanic guy needs a little guidance again.

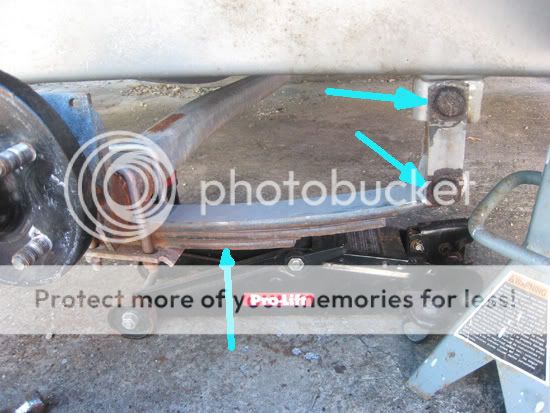

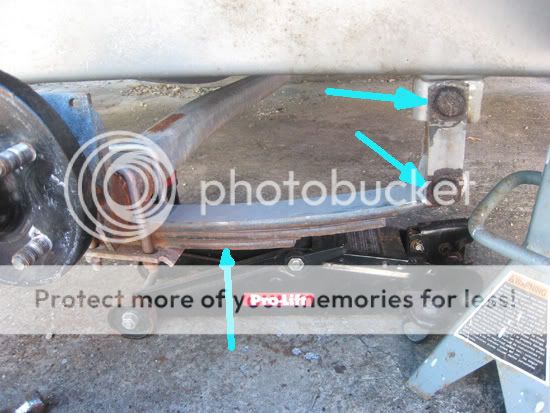

I think the part in my photo is called a leaf spring.

I have two and they are getting rusty real fast from

being dipped in ocean water. I hose them with fresh

water every time they get salt water wet.

My question is several parts.

1. Is this thing under tremendous compression like the

coil springs in my TR6? If so, how do I decompress it?

2. The very rusty bolts, indicated with blue arrows, are

1/2" SAE grade #5. Can I replace them with stainless steel?

3. Do the leaf springs come apart into layers? If so,

should I heavy grease coat the individual slabs of steel?

or paint them with Eastwood rust compound? Or both techniques?

Many thanks--- no fishing for me until the rust problem is

properly refurbished.

dale /bcforum/images/%%GRAEMLIN_URL%%/wall.gif

I think the part in my photo is called a leaf spring.

I have two and they are getting rusty real fast from

being dipped in ocean water. I hose them with fresh

water every time they get salt water wet.

My question is several parts.

1. Is this thing under tremendous compression like the

coil springs in my TR6? If so, how do I decompress it?

2. The very rusty bolts, indicated with blue arrows, are

1/2" SAE grade #5. Can I replace them with stainless steel?

3. Do the leaf springs come apart into layers? If so,

should I heavy grease coat the individual slabs of steel?

or paint them with Eastwood rust compound? Or both techniques?

Many thanks--- no fishing for me until the rust problem is

properly refurbished.

dale /bcforum/images/%%GRAEMLIN_URL%%/wall.gif

Hey there Guest!

Hey there Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

A friendly reminder - be careful what links you click on here. If a link is posted by someone you don't know, or the URL looks fishy, DON'T CLICK. Spammers sometimes post links that lead to sites that can infect your computer, so be mindful what you click.

A friendly reminder - be careful what links you click on here. If a link is posted by someone you don't know, or the URL looks fishy, DON'T CLICK. Spammers sometimes post links that lead to sites that can infect your computer, so be mindful what you click.