CJD

Yoda

Offline

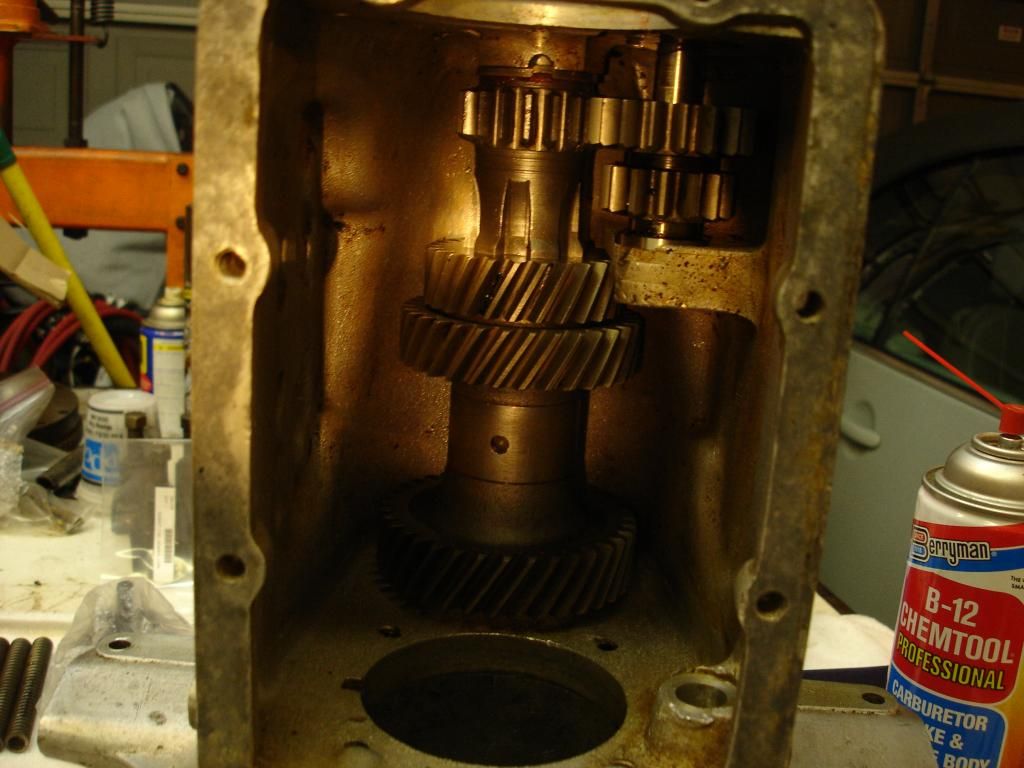

This thread will be another one of my long drawn out "How to's". Again, I'm not trying to replace the manual, just adding pictures to the dull verbiage. Anybody feel free to jump in with other tips and tricks as you see fit. Gearbox inspection and assembly is a bit of an art, and no tip can be ignored.

I bought my first car when I was 15. It was an ex-Border Patrol IH Scout. What a deal at $500! After putting everything I had into it, it dropped the countershaft in week two of ownership. Bummer. So, at age 15 and 2 weeks I had to learn how to rebuild a gearbox and transfer case. I remember working an auto manual for my first time, and it was more of a guide than a manual. You get it all torn down and all it says is "inspect" all parts and replace as necessary. What? That's it? Huh?? What about...???

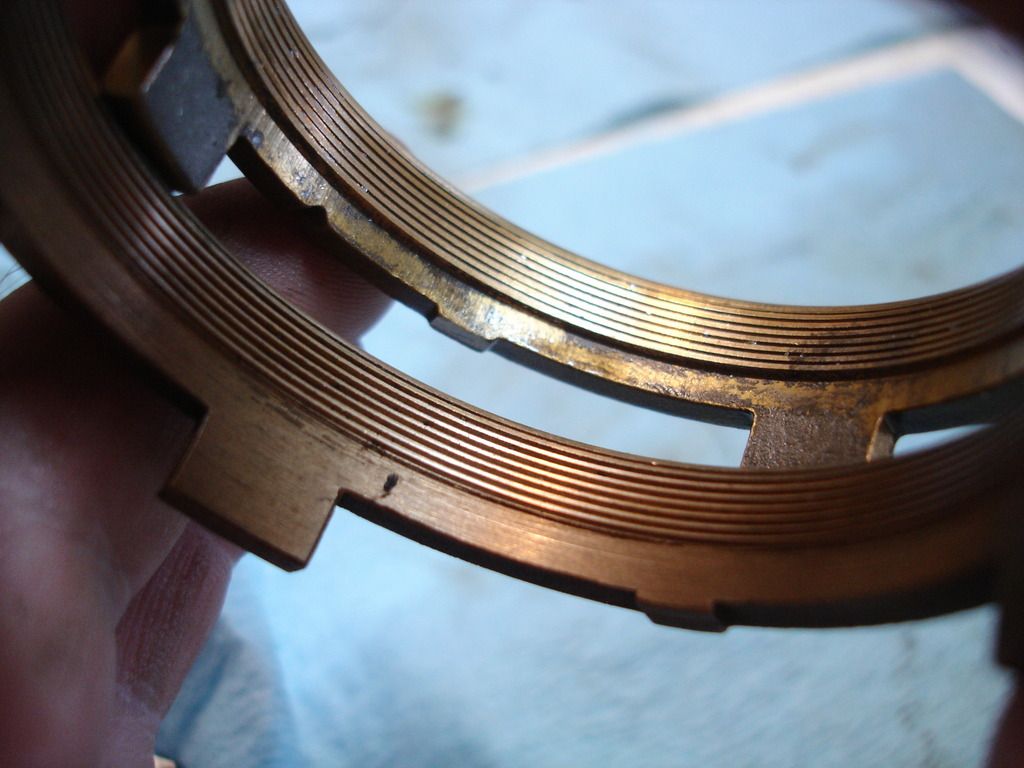

Every time you miss a shift over the 100k+ mile lifetime of a gearbox, you are wearing the gears. Unless you have unlimited pockets...which was not me at 15, and still not to this day...you have to figure out how much wear is acceptable, and how much is worthy of replacing the gear. Well, after more than 40 years and several dozen gearbox rebuilds, I can definitively say what will work and what is going to "P you O" every time you shift! This stuff is not in books. I learned it by rebuilding my Muncy 6 times for bad blocker rings, and cussing at a stop light when the light is green and the TR3 tranny won't stick 1st gear with everyone honking at me.

So, here goes...be sure to add anything you think will help others as we go...

I bought my first car when I was 15. It was an ex-Border Patrol IH Scout. What a deal at $500! After putting everything I had into it, it dropped the countershaft in week two of ownership. Bummer. So, at age 15 and 2 weeks I had to learn how to rebuild a gearbox and transfer case. I remember working an auto manual for my first time, and it was more of a guide than a manual. You get it all torn down and all it says is "inspect" all parts and replace as necessary. What? That's it? Huh?? What about...???

Every time you miss a shift over the 100k+ mile lifetime of a gearbox, you are wearing the gears. Unless you have unlimited pockets...which was not me at 15, and still not to this day...you have to figure out how much wear is acceptable, and how much is worthy of replacing the gear. Well, after more than 40 years and several dozen gearbox rebuilds, I can definitively say what will work and what is going to "P you O" every time you shift! This stuff is not in books. I learned it by rebuilding my Muncy 6 times for bad blocker rings, and cussing at a stop light when the light is green and the TR3 tranny won't stick 1st gear with everyone honking at me.

So, here goes...be sure to add anything you think will help others as we go...

Hey there Guest!

Hey there Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

A friendly reminder - be careful what links you click on here. If a link is posted by someone you don't know, or the URL looks fishy, DON'T CLICK. Spammers sometimes post links that lead to sites that can infect your computer, so be mindful what you click.

A friendly reminder - be careful what links you click on here. If a link is posted by someone you don't know, or the URL looks fishy, DON'T CLICK. Spammers sometimes post links that lead to sites that can infect your computer, so be mindful what you click.