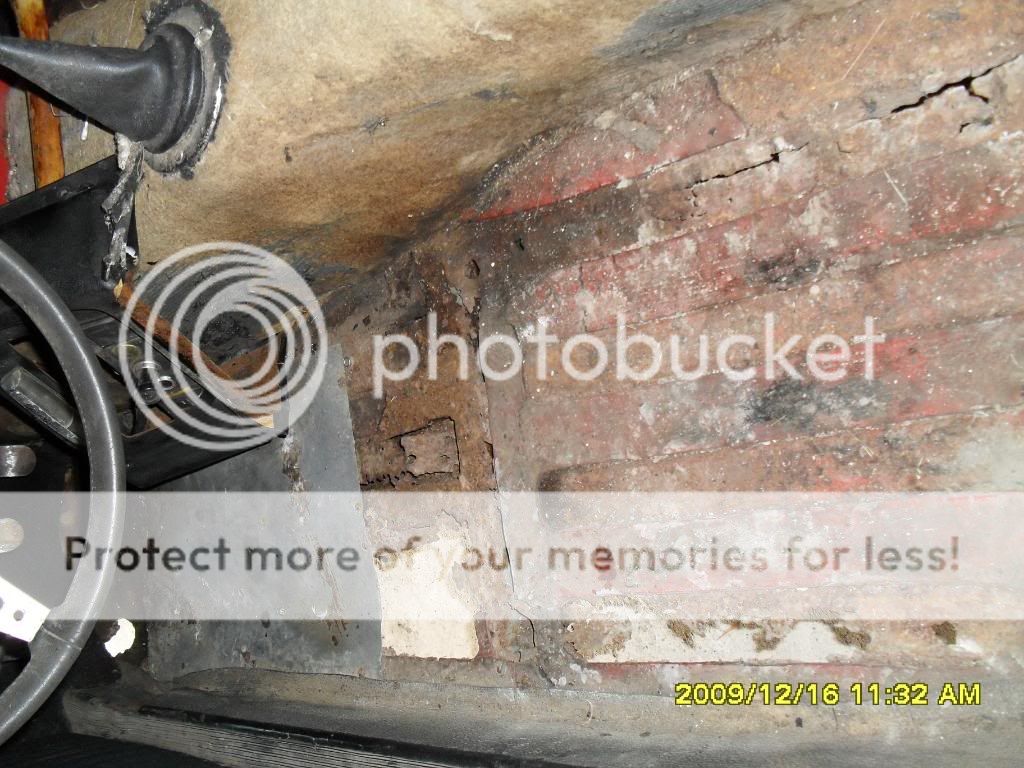

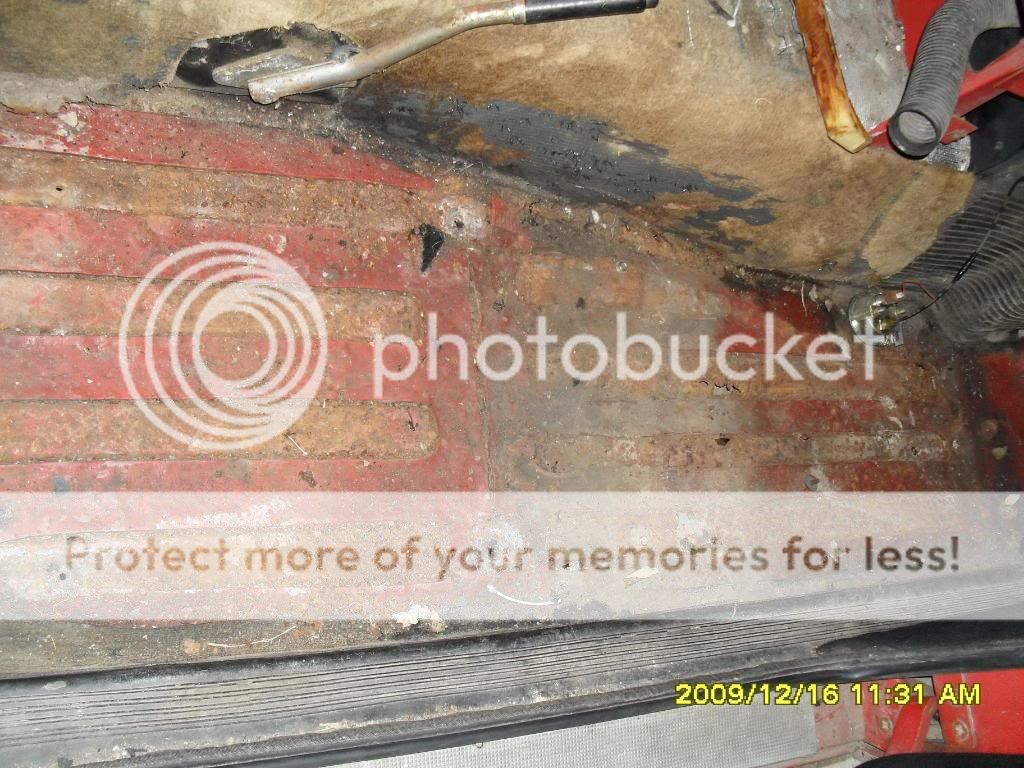

Well, we are ready to start on the replacement of floor pans. First thing, of course, is getting the old ones out! Can someone give us some guidance and some "what NOT to do's"?

Tony, you mentioned awhile back that you could walk us through it and explain how not to have to weld them...we'd appreciate the assistance.

Any suggestions on who to order from? Any preference between Victoria British and Moss?

Thanks for any help.

Tony, you mentioned awhile back that you could walk us through it and explain how not to have to weld them...we'd appreciate the assistance.

Any suggestions on who to order from? Any preference between Victoria British and Moss?

Thanks for any help.

Hey there Guest!

Hey there Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

with Bob. If it's only the floor pans you're replacing, bracing probably isn't an issue. Just grabbed the book I mentioned earlier, and there's no mention of preliminary bracing. Sill and crossmember changeouts will be a different animal, however.

with Bob. If it's only the floor pans you're replacing, bracing probably isn't an issue. Just grabbed the book I mentioned earlier, and there's no mention of preliminary bracing. Sill and crossmember changeouts will be a different animal, however.

A friendly reminder - be careful what links you click on here. If a link is posted by someone you don't know, or the URL looks fishy, DON'T CLICK. Spammers sometimes post links that lead to sites that can infect your computer, so be mindful what you click.

A friendly reminder - be careful what links you click on here. If a link is posted by someone you don't know, or the URL looks fishy, DON'T CLICK. Spammers sometimes post links that lead to sites that can infect your computer, so be mindful what you click.